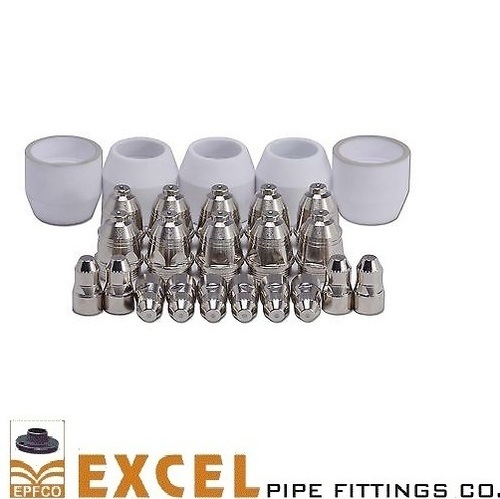

Plasma Consumables

Plasma Consumables Specification

- Flexibility

- Rigid

- Tensile Strength

- High (Specific to grade)

- Diameter

- Varies as per part

- Coating Type

- Silver Plated

- Temperature Range

- Up to 800C

- Yield Strength

- High (Specific to grade)

- Connection Type

- Male/Female

- Tolerance

- High precision

- Thread Type

- Fine Thread

- Sealing Type

- Precision Fit

- Product Type

- Plasma Consumables

- Material

- Copper, Silver Plated

- Connection

- Press Fit/Screw

- Shape

- Round

- Standard

- Industrial Standard

- Surface Treatment

- Polished

- Outer Diameter

- 8 mm - 14 mm (varies by model)

- Section Shape

- Cylindrical

- Length

- 20 mm - 60 mm (varies by piece)

- Thickness

- 1-3 mm (varies by part)

- Color

- Copper/Gold

- Usage

- Plasma Cutting Torch

- Rated Pressure

- Standard Shop Pressure

- Application

- CNC Plasma Cutting Machine

- Material Grade

- High Purity Grade

- Hardness

- 60-80 HRB

- Cutting Capacity

- Up to 25 mm mild steel

- Packaging

- Box, Carton

- Part Types

- Electrode, Nozzle, Swirl Ring, Shield Cap

- Manufacturing Process

- CNC Machined/Precision Casting

- Heat Resistance

- Excellent Thermal Conductivity

- Wear Resistance

- High, Extended Life

- MOQ

- As per requirement

- Compatibility

- Fits most standard plasma torches

Plasma Consumables Trade Information

- Minimum Order Quantity

- 300 Bags

- FOB Port

- Navaseva

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- BOXES

- Main Domestic Market

- Manipur, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Punjab, Rajasthan, Sikkim, Tamil Nadu, Tripura, West Bengal, Nagaland, Uttar Pradesh, Haryana, Gujarat, North India, Telangana, Kerala, Central India, Odisha, Chhattisgarh, All India

- Certifications

- ISO 9001

About Plasma Consumables

| Brand | Plasma Cutting Consumable |

| Model | As per std / customize / requirement |

| Warranty | As per std / customize / requirement |

| Usage/Application | As per std / customize / requirement |

| Consumable Type | Electrodes, Torch, Spare Part |

Complete range of Plasma consumable as per requirement

Hypertherm

Thermaldynamics

Panasoni

Kjelberg

Koike

Precision Engineering for Optimal Plasma Cutting

Plasma consumables are crafted using CNC machining and precision casting techniques, ensuring each electrode, nozzle, swirl ring, and shield cap meets stringent quality standards. This advanced manufacturing results in high precision, long life, and reliable performance during demanding plasma cutting operations, providing users with consistently superior cut quality and reduced maintenance downtime.

Versatile Compatibility and Robust Construction

Designed to fit most standard plasma torches, these consumables are built with high-purity copper or silver-plated materials for outstanding thermal and electrical conductivity. The components maintain their integrity up to 800C, delivering great wear resistance and mechanical strength, whether used for small workshops or industrial-scale CNC plasma cutting.

FAQs of Plasma Consumables:

Q: How do I determine which plasma consumable part type is needed for my plasma torch?

A: To select the correct part typeelectrode, nozzle, swirl ring, or shield caprefer to your torchs compatibility chart or user manual. These consumables are universally engineered to fit most standard torches, with varying diameters, thicknesses, and connection types (press fit or screw) to ensure optimal performance.Q: What materials are used in these plasma consumables, and what benefits do they offer?

A: Our consumables are constructed from high purity grades of copper and are often silver-plated for enhanced electrical conductivity and heat resistance. This provides excellent thermal management, reduced wear, and extended life in high-temperature plasma cutting environments.Q: When should I replace plasma torch consumables for best cutting results?

A: It is recommended to inspect consumables regularly for wear, such as erosion on the electrode or nozzle or reduced cutting quality. Replace parts when you notice signs of degradation to maintain optimal cut precision, especially during high-volume operations or when cutting up to 25 mm mild steel.Q: Where should plasma consumables be stored to preserve their quality?

A: Store consumables in their original box or carton packaging in a dry, dust-free environment. Avoid exposure to moisture and extreme temperatures to maintain the integrity of copper or silver-plated finishes and prevent premature wear or oxidation.Q: What is the manufacturing process for these plasma consumables?

A: Each component is produced using advanced CNC machining or precision casting methods, followed by polishing and silver plating (if applicable) to achieve a high-precision, cylindrical shape. The process ensures tight tolerances and a smooth surface for reliable connection and optimal plasma performance.Q: How do these consumables benefit my CNC plasma cutting operations?

A: Enhanced by excellent wear resistance, high hardness, and superior thermal conductivity, these consumables provide extended operational life and consistent cut quality. This reduces downtime and replacement costs, making them a cost-effective choice for manufacturers, exporters, and suppliers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Spare Parts Category

Thermal Dynamics Electrode

Price 1000 INR / Bag

Minimum Order Quantity : 300 Bags

Standard : Other, ISO 6848

Material Grade : High Conductivity Copper

Temperature Range : Up to 400C

Messer Oxyfuel Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Standard : Other, OEM Standard

Material Grade : High Conductivity Copper Alloy

Temperature Range : 20C to 400C

Koike Plasma Consumables

Price 300 INR / Bag

Minimum Order Quantity : 300 Bags

Standard : Other, OEM Compatible

Material Grade : Premium Industrial Grade

Temperature Range : Up to 500C

Hypertherm Coolant

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Standard : Other, Meets Hypertherm Plasma System Requirements

Material Grade : Premium Grade

Temperature Range : Up to 60C (140F)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry