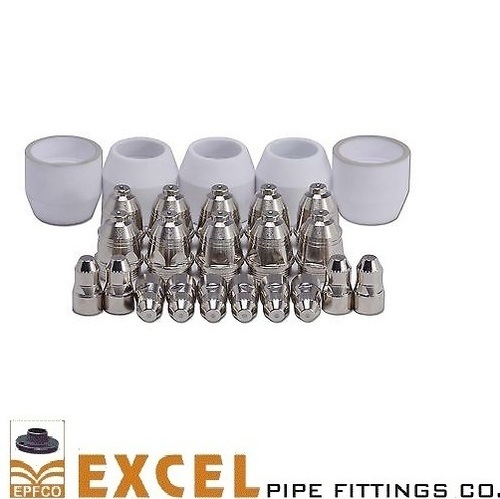

Messer Oxyfuel Consumables

MOQ : 300 Bags

Messer Oxyfuel Consumables Specification

- Tolerance

- 0.02 mm

- Temperature Range

- -20C to 400C

- Flexibility

- Rigid

- Diameter

- 6 mm, 9 mm, 12 mm (as per tip)

- Tensile Strength

- >350 MPa

- Connection Type

- Threaded/Slip Type

- Bend Radius

- Rigid (Not Applicable)

- Thread Type

- BSP/Metric

- Coating Type

- Anti-corrosive Coating

- Yield Strength

- 220 MPa

- Sealing Type

- Metal to Metal

- Product Type

- Oxyfuel Consumables

- Material

- Copper Alloy, Brass

- Connection

- Threaded/Push fit

- Shape

- Cylindrical, Nozzle, Tip

- Standard

- OEM Standard

- Surface Treatment

- Polished, Coated

- Outer Diameter

- 10 mm to 25 mm

- Section Shape

- Circular

- Length

- 25 mm to 100 mm

- Thickness

- 2 mm to 6 mm (as per part)

- Color

- Copper, Golden

- Usage

- Oxyfuel Cutting, Welding, Heating

- Rated Pressure

- 6 Bar

- Application

- Gas Cutting Equipment, Welding Torch

- Material Grade

- High Conductivity Copper Alloy

- Maintenance

- Periodic cleaning required

- Storage Conditions

- Store in dry, dust-free environment

- Replacement Cycle

- Depends on usage; typically after significant wear

- Consumable Types

- Cutting Nozzle, Welding Tip, Heating Nozzle, Gas Lenses

- Packing Type

- Box/Blister Pack

- Corrosion Resistance

- High

- Hardness

- 8590 HRB

- Port Type

- Standard ISO fitting

- Compatibility

- Universal (fits Messer torches and most standard handles)

- Gas Compatibility

- Acetylene, Oxygen, LPG

- Machinability

- Excellent

Messer Oxyfuel Consumables Trade Information

- Minimum Order Quantity

- 300 Bags

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

About Messer Oxyfuel Consumables

| Model | As Per Std / Customize / Requirement |

| Material | As Per Requirement |

| Fuel Gas Type | Oxy-Acetylene |

| Torch Type | Cutting torch |

| Consumable Type | Spare Part, Electrodes, Torch |

| Customisation | Customised |

Messer Oxyfuel Consumables

Messer Spares

Messer Gricut 1230-PMYF

Messer Gricut 1230-PMYF

Messer Vadura1210-A

Messer Vadura 1215-A

Messer Vadura 1215-A A716.15941 Cutting Nozzle 3-5mm A716.15942 Cutting Nozzle 6-10mm A716.15943 Cutting Nozzle 10-25mm A716.15944 Cutting Nozzle 25-40mm A716.15945 Cutting Nozzle 40-60mmA716.15946 Cutting Nozzle 60-100mm A716.15947 Cutting Nozzle 100-150mm A716.15948 Cutting Nozzle 150-230mmA716.15949 Cutting Nozzle 230-300mm A716.15950 Heating Nozzle 3-150mm A716.15951 Heating Nozzle 150-300mm

Messer Vadura 1210-A

A716.15761 Cutting Nozzle 3-5mm A716.15762 Cutting Nozzle 6-10mm A716.15763 Cutting Nozzle 10-25mm A716.15764 Cutting Nozzle 25-50mm A716.15765 Cutting Nozzle 50-80mm A716.15766 Cutting Nozzle 80-100mm A716.15769 Cutting Nozzle 100-150mm A716.15948 Cutting Nozzle 150-230mm A716.15949 Cutting Nozzle 230-300mm A716.15770 Heating Nozzle 3-150mm A716.15951 Heating Nozzle 150-300mm

Messer Gricut 1230-PMYF

A716.15901 Cutting Nozzle 3-10mm A716.15902 Cutting Nozzle 7-15mm A716.15903 Cutting Nozzle 15-25mmA716.15904 Cutting Nozzle 25-40mm A716.15905 Cutting Nozzle 40-60mm A716.15906 Cutting Nozzle 60-100mm

Messer Gricut1280-PMYF

A716.15927 Cutting Nozzle 100-200mm A716.15928 Cutting Nozzle 200-250mm A716.15929 Cutting Nozzle 250-300mm A716.15931 Heating Nozzle 100-300mm

Exceptional Compatibility and Versatile Applications

Messer Oxyfuel Consumables are designed with universal fittings that seamlessly match Messer torches and standard handles. Whether you are involved in industrial cutting, welding, or heating, these consumables offer broad adaptability for a range of tasks in fabrication and maintenance workshop environments.

Durable Construction and Superior Performance

Made from high-conductivity copper alloy and brass, each consumable guarantees exceptional performance. Their robust anti-corrosive coatings and precise machining (tolerance 0.02 mm) ensure long service life, even under tough working conditions. The OEM standard designs fit perfectly, reducing system wear and increasing operational efficiency.

Reliable Packing and Safe Storage

Each consumable is securely packed in box or blister packaging to prevent damage during transit. For best results, store your Messer Oxyfuel Consumables in a dry, dust-free environment. This precaution preserves the products integrity, ensuring readiness for immediate use when you need it most.

FAQs of Messer Oxyfuel Consumables:

Q: How do I determine if Messer Oxyfuel Consumables are compatible with my torch?

A: These consumables are universally designed to fit Messer torches and most standard handles. Check your torchs fitting typeif it supports standard ISO or BSP/Metric threads, these consumables will be compatible.Q: What types of gases can be used with these consumables?

A: Messer Oxyfuel Consumables are compatible with acetylene, oxygen, and LPG gases, making them suitable for a variety of operations including cutting, welding, and heating tasks.Q: When should I replace my oxyfuel consumables?

A: Replace consumables when you observe significant wear or diminished cutting/welding quality. The typical replacement cycle depends on usage intensity and operating conditions.Q: Where should I store Messer Oxyfuel Consumables for optimal lifespan?

A: Store the consumables in a dry, dust-free environment to maintain their high corrosion resistance and guarantee long-term reliability and performance.Q: What maintenance is required to ensure optimal performance of these consumables?

A: Routine cleaning and inspection are recommended to remove debris or oxidation build-up. Periodic maintenance preserves the integrity and safety of your cutting or welding process.Q: How do the polished and coated surfaces benefit the metalworking process?

A: Polished and anti-corrosive coated surfaces reduce oxidation, minimize friction, and extend the lifespan of each consumable, resulting in smoother operations with reduced downtime.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Plasma Spare Parts Category

Plasma Torches

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Thickness : 26 mm (tip body)

Color : Copper/Gold/Silver

Length : 150220 mm

Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Thickness : 13 mm (varies by part)

Color : Copper/Gold

Length : 20 mm 60 mm (varies by piece)

Hypertherm Nozzle

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Thickness : 2.5 mm

Color : Copper

Length : 27 mm

Thermal Dynamics Nozzle

Price 200 INR / Bag

Minimum Order Quantity : 300 Bags

Thickness : 1.2 mm

Color : Copper / Silver

Length : 32 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry