Thermal Dynamics Nozzle

Price 200 INR/ Bag

Thermal Dynamics Nozzle Specification

- Sealing Type

- Precision Fit

- Yield Strength

- 70 MPa

- Tolerance

- 0.05 mm

- Temperature Range

- -20C to 250C

- Diameter

- 1.2 mm

- Flexibility

- Rigid

- Coating Type

- Nickel Coating

- Tensile Strength

- 235 MPa

- Thread Type

- Non-threaded

- Connection Type

- Slip On

- Product Type

- Plasma Cutting Nozzle

- Material

- Copper Alloy

- Connection

- Push-fit

- Shape

- Cylindrical

- Standard

- ANSI/ISO Standard

- Surface Treatment

- Nickel Plated

- Outer Diameter

- 13 mm

- Section Shape

- Round

- Length

- 32 mm

- Thickness

- 1.2 mm

- Color

- Copper / Silver

- Usage

- Plasma Cutting Torch Consumable

- Rated Pressure

- 6 bar

- Application

- Industrial Metal Cutting

- Material Grade

- High Conductivity Copper

- Corrosion Resistance

- High

- Orifice Size

- 1.2 mm

- Cutting Process

- Plasma Arc

- Current Rating

- Up to 120A

- Compatible Torch Models

- Thermal Dynamics SL60/SL100

- Lifespan

- Extended, depending on usage

- Package Contains

- 1 Nozzle

- Weight

- 18 g

- Part Number

- 9-8207

Thermal Dynamics Nozzle Trade Information

- Minimum Order Quantity

- 300 Bags

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

About Thermal Dynamics Nozzle

| Brand | THERMAL DYNAMIC |

| Model | as per std / customize / requirement |

| Packaging (quantity per box) | as per std / customize / requirement |

| Fuel Gas Type | as per std / customize / requirement as per std / customize / requirement |

| Customisation | Customised |

| Cutting Capacity (mm) | as per std / customize / requirement |

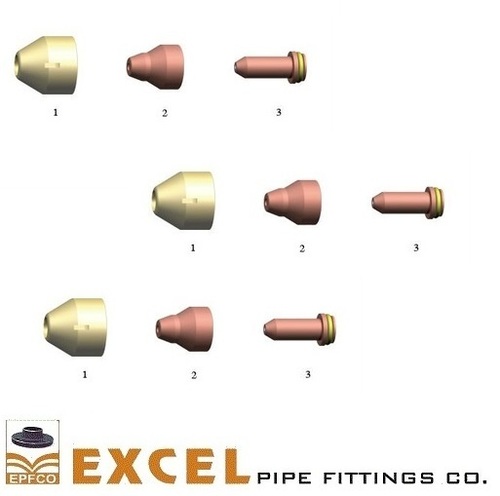

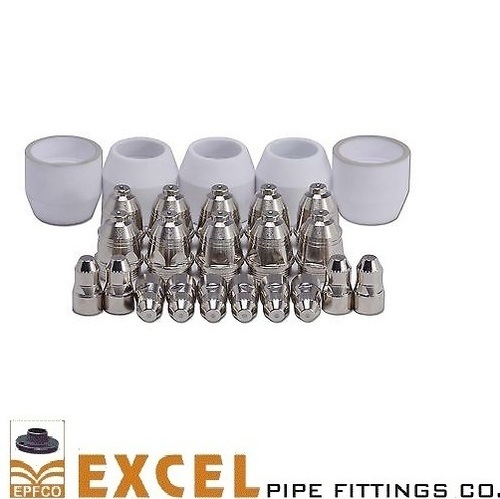

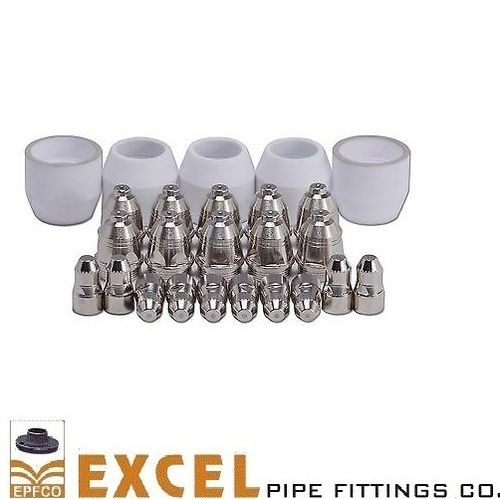

We are authorised distributor for Thermal Dynamics Plasma cutting machine and consumables. The above image is used as a spare part in Thermal Dynamics Plasma torch. It is called Nozzle as well as Tip.

Request

Callback

Designed for Precision Plasma Cutting

Engineered to meet stringent ANSI/ISO standards, the Thermal Dynamics 9-8207 nozzle features a 1.2 mm orifice and precision fit tolerance of 0.05 mm. Its round, push-fit cylindrical shape ensures consistent plasma arc flow, supporting clean and accurate cuts in industrial environments. Nickel plating and high-conductivity copper core provide optimal durability and conductivity.

User-friendly Installation and Compatibility

This nozzle is compatible with Thermal Dynamics SL60 and SL100 plasma cutting torches. The slip-on, push-fit connection ensures quick and secure attachment without the need for threading. With a standard outer diameter of 13 mm and length of 32 mm, it fits seamlessly, offering minimal downtime and greater workflow efficiency.

FAQs of Thermal Dynamics Nozzle:

Q: How do I install the Thermal Dynamics 9-8207 nozzle on my plasma torch?

A: The 9-8207 nozzle features a push-fit, slip-on connection, making installation straightforward. Simply align the nozzle with your SL60 or SL100 plasma torch and press firmly until it is securely seated. No threading tools are required.Q: What are the key benefits of using this nozzle for industrial metal cutting?

A: This nozzle offers high corrosion resistance, a precise 1.2 mm orifice for clean cuts, and an extended lifespan. Its high-conductivity copper alloy core ensures efficient plasma arc performance, while the nickel plating protects against wear in demanding industrial environments.Q: When should I replace the nozzle?

A: Nozzle replacement depends on usage and the quality of the materials cut. For optimal performance and cut quality, inspect the nozzle regularly and replace it when cuts become rough, the orifice shows visible wear, or you notice reduced efficiency.Q: Where can this nozzle be used?

A: The 9-8207 nozzle is suitable for a variety of industrial settings, including manufacturing facilities, fabrication shops, and construction sitesanywhere precision plasma arc metal cutting is required.Q: What is the process for maintaining the nozzles performance?

A: To maintain peak performance, regularly clean the nozzle to remove metal slag or buildup. Inspect for physical damage and ensure the fit remains tight and true. Proper maintenance extends its lifespan and ensures superior cut quality.Q: What usage limits and environmental conditions does this nozzle support?

A: This nozzle can operate in environments ranging from -20C to 250C at pressures up to 6 bar. Its rigid structure and nickel-plated surface offer robustness under industrial stress, while the high-conductivity copper maintains efficiency across varying job conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Spare Parts Category

Kjellberg Plasma Consumables

Price Range 500.00 - 5000.00 INR / Bag

Minimum Order Quantity : 300 Bags

Shape : Other, Round/Varied

Standard : Other, OEM/Compatible with Kjellberg

Material : Other , Copper Alloy

Application : other, Sheet Metal Cutting/Industrial Cutting

Plasma Torches

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Shape : Other, Cylindrical

Standard : Other, ISO 9001

Material : Other , Copper, Brass, Ceramic

Application : other, CNC Plasma Machines, Manual Plasma Cutting

Messer Oxyfuel Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Shape : Other, Cylindrical, Nozzle, Tip

Standard : Other, OEM Standard

Material : Other , Copper Alloy, Brass

Application : other, Gas Cutting Equipment, Welding Torch

Panasonic Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Shape : Other, Round, Cylindrical

Standard : Other, OEM Standard

Material : Other , Copper Alloy, Ceramic

Application : other, Metal Cutting, Fabrication

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry