Kjellberg Plasma Consumables

Kjellberg Plasma Consumables Specification

- Diameter

- Varies (part specific)

- Coating Type

- Uncoated/Polished Surface

- Flexibility

- Rigid

- Tensile Strength

- High - suitable for industrial use

- Sealing Type

- Metal-to-metal

- Connection Type

- Consumable-Fit

- Temperature Range

- Up to 500C

- Yield Strength

- High

- Thread Type

- None/Press Fit

- Tolerance

- High precision

- Product Type

- Plasma Consumables

- Material

- Copper Alloy

- Connection

- Press Fit

- Shape

- Round/Varied

- Standard

- OEM/Compatible with Kjellberg

- Surface Treatment

- Polished

- Outer Diameter

- Varies (typically 1-20 mm)

- Section Shape

- Cylindrical

- Length

- Varies as per part type

- Thickness

- Custom/Varied

- Color

- Copper/Bronze

- Usage

- Plasma Cutting Machine

- Rated Pressure

- Up to 6 bar

- Material Grade

- Industrial Grade Copper

- Application

- Sheet Metal Cutting/Industrial Cutting

- Process Type

- Air Plasma Cutting

- Replacement Interval

- Per manufacturer instructions

- Part Types Available

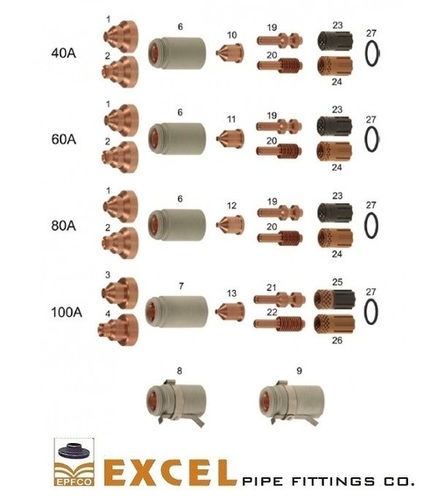

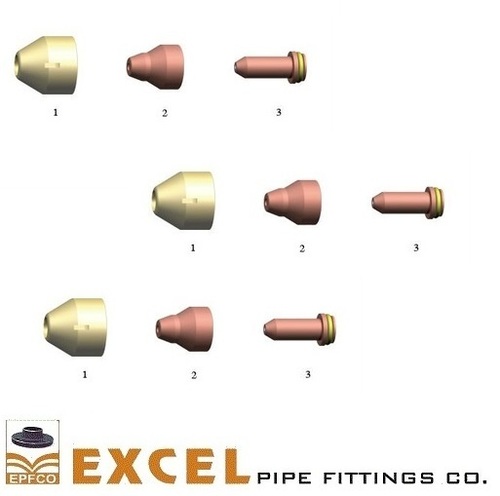

- Nozzle, Electrode, Swirl Ring, Shield Cap, Retaining Cap, Spacer

- Packaging

- Blister pack, box

- Max Current Supported

- Up to 400A depending on the part

- Compatibility

- Kjellberg Plasma Cutting Systems (e.g., HiFocus, SmartFocus, FineFocus)

- Cut Quality

- Fine, smooth edge with minimal dross

Kjellberg Plasma Consumables Trade Information

- Minimum Order Quantity

- 300 Bags

- FOB Port

- Navaseva

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- BOXES

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, East India, Assam, Arunachal Pradesh, Bihar, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Mizoram, Meghalaya, Manipur, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttar Pradesh, Maharashtra, Haryana, Delhi, Gujarat, South India, Madhya Pradesh, North India, Punjab, Andhra Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh, All India

- Certifications

- ISO 9001

About Kjellberg Plasma Consumables

| Warranty | as per std / customize / requirement |

| Packaging (quantity per box) | as per std / customize / requirement |

| Material | as per std / customize / requirement |

| Brand | Kjellberg Plasma Consumable |

| Model | As Per Spec |

| Max Flame Temperature (degree Celsius) | as per std / customize / requirement |

| Torch Type | Cutting torch |

-

Kjellberg Plasma Consumables PB-S70/75 Parts 11.828.921.300 Electrode, K2 XL, Silverline, O2 12.37790 Nozzle Cap 12.40860 Gas Guide Cap PB-S77 Parts 11.828.921.300 Electrode, K2 XL, Silverline, O2 11.833.101.158 Swirl Gas Cap, 5.0MM 12.37790 Nozzle Cap PB-S80 Parts 11.836.921.300 Electrode, Silverline, 02/AIR, T012 11.836.921.153 Gas Guide, T101 11.833.101.155 Swirl Gas Cap, 3.5MM, V4335 PerCut 101 Parts 11.835.201.081 Protection Cap, Z501 C106-1001 Electrode, Silverline, O2, Z002 11.835.421.3101 Electrode, Silverline, O2, Z012 PerCut 160i Parts 11.835.201.081 Protection Cap, Z501 11.835.221.153 Gas Guiding Cap, 0.4MM, O2, Z101 11.835.401.1571 Swirl Gas Cap, 4.0MM, Z4140

Request

Callback

High-Precision Kjellberg Consumable Range

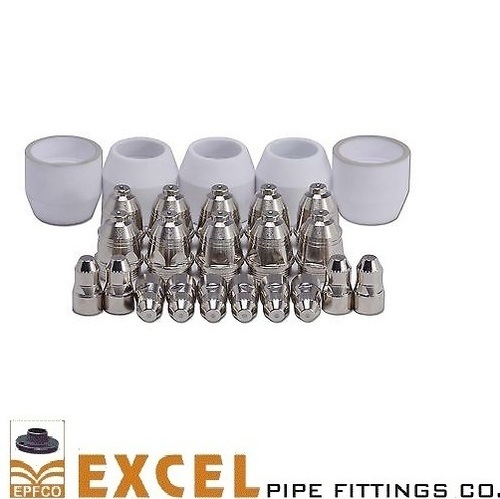

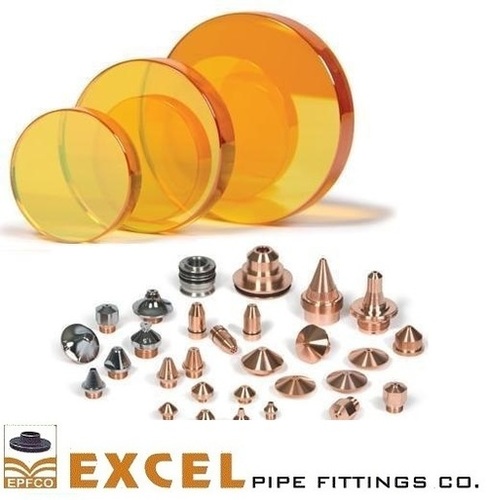

The range covers nozzles, electrodes, swirl rings, shield caps, retaining caps, and spacers, each tailored to meet demanding plasma cutting needs. Manufactured with industrial-grade copper alloys, these consumables undergo polishing treatments to maximize conductivity and reduce wear, supporting consistent and efficient cutting at variable currents up to 400A.

Seamless Compatibility and OEM Standards

Kjellberg Plasma Consumables are engineered to fit HiFocus, SmartFocus, and FineFocus systems. Designed with high tolerance and precise dimensions, they provide a metal-to-metal seal through press fit construction, ensuring secure and stable performance in industrial applications.

Cut Quality and Performance Assurance

Experience immaculate edge quality with minimal dross, thanks to precision manufacturing and polished surface finishes. Each consumable maintains structural integrity at rated pressures up to 6 bar and operating temperatures up to 500C, maximizing longevity while supporting rigorous cutting schedules.

FAQs of Kjellberg Plasma Consumables:

Q: How do I determine which Kjellberg plasma consumable is suitable for my cutting system?

A: Select consumables based on system compatibility, such as HiFocus, SmartFocus, or FineFocus. Always reference your plasma systems manual and follow manufacturer recommendations for optimal part type and sizing.Q: What benefits do copper alloy and polished surfaces offer for these plasma consumables?

A: Copper alloy ensures excellent electrical conductivity and durability, while polished surfaces reduce residue buildup and prolong component life, resulting in cleaner cuts and consistent performance.Q: When should I replace Kjellberg plasma consumables during operation?

A: Replace consumables according to the interval specified by the manufacturer or when you observe reductions in cut quality, increased dross, or any visible wear on the parts.Q: Where are Kjellberg plasma consumables used?

A: These consumables are primarily used in industrial and sheet metal plasma cutting applications across manufacturing, fabrication, and metalworking industries, particularly on plasma cutting machines that support air plasma processes.Q: How does the consumable connection system work in Kjellberg plasma cutters?

A: Consumables are designed for a press-fit, metal-to-metal connection, ensuring a reliable and leak-proof fit without threaded components, which enhances setup ease and operational stability.Q: What process type do these consumables support, and what quality of cut can I expect?

A: They are intended for air plasma cutting processes, offering fine, smooth edges with minimal dross and high precision, particularly when cutting varied sheet metal thicknesses.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Spare Parts Category

Hypertherm Consumables

Price 5000 INR / Bag

Minimum Order Quantity : 300 Bags

Standard : Other, ISO 9001 Certified

Product Type : Other, Plasma Cutter Consumables

Color : Copper

Messer Oxyfuel Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Standard : Other, OEM Standard

Product Type : Other, Oxyfuel Consumables

Color : Copper, Golden

Esab Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Standard : Other, ISO Certified, Compatible with ESAB Cutmaster Series

Product Type : Other, Plasma Consumables

Color : Copper, Silver, Metallic

Trumpf Laser Consumable

Price 500 INR / Bag

Minimum Order Quantity : 300 Bags

Standard : Other, OEM/Compatible

Product Type : Other, Laser Consumable

Color : Copper

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry