Hypertherm Consumables

Price 5000 INR/ Bag

Hypertherm Consumables Specification

- Tensile Strength

- 350 MPa

- Bend Radius

- Fixed

- Tolerance

- 0.02 mm

- Coating Type

- Nickel Coated

- Temperature Range

- -10C to 80C

- Yield Strength

- 280 MPa

- Thread Type

- Non-Threaded

- Diameter

- 0.8 mm Nozzle

- Connection Type

- Slip On

- Sealing Type

- Precision Fit

- Flexibility

- Rigid

- Product Type

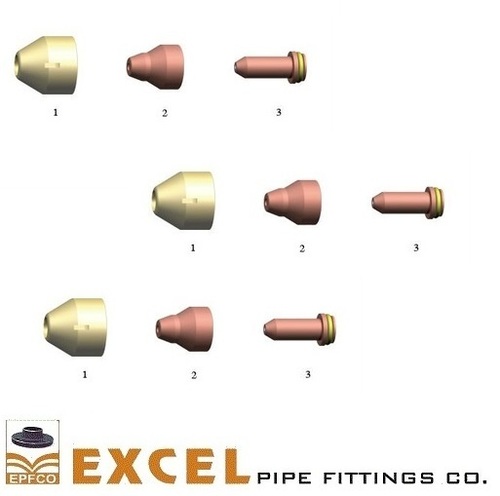

- Plasma Cutter Consumables

- Material

- Copper Alloy

- Connection

- Press Fit

- Shape

- Round

- Standard

- ISO 9001 Certified

- Surface Treatment

- Nickel Plated

- Outer Diameter

- 8 mm

- Section Shape

- Cylindrical

- Length

- 23 mm

- Thickness

- 2 mm

- Color

- Copper

- Usage

- Industrial Plasma Cutting

- Rated Pressure

- 6.5 bar

- Material Grade

- High Conductivity

- Application

- Suitable for Hypertherm Plasma Cutting Machines

Hypertherm Consumables Trade Information

- Minimum Order Quantity

- 300 Bags

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

About Hypertherm Consumables

| Brand | As Per Std / Customize / Requirement |

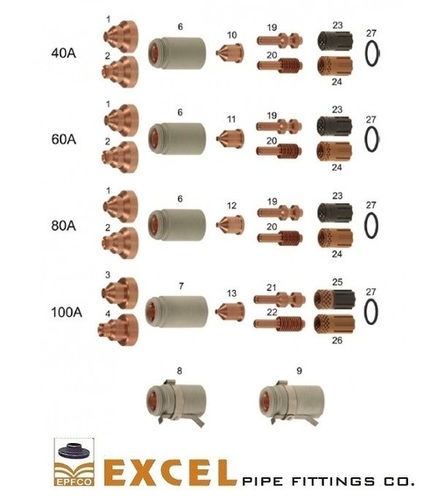

| Model | HYPERTHERMS |

| Consumable Type | Spare Part |

| Material | as per std / customize / requirement |

| Automation Grade | Manual |

| Application | Plasma Source Consumable |

| Warranty | As Per Std / Customize / Requirement |

We are offering a qualitative range of Hypertherm Consumables which is extensively used in the cutting of electrically conductive metals. These consumables offered by us are manufactured in accordance with the quality standards. Our products are available in various sizes and specification as per application requirement.

Features:

- Easy to use

- Dimensional accuracy

- Non-corrosive

- Low maintenance

Precision-Engineered for Performance

Manufactured using advanced CNC machining and adhering to ISO 9001 standards, these Hypertherm consumables guarantee exceptional precision and durability. Nickel plating enhances corrosion resistance, ensuring consistent plasma cutting quality. The components suit a range of industrial applications, catering to users who demand efficiency and reliability.

Optimal Compatibility and Easy Replacement

Designed specifically for Hypertherm Powermax series (45/65/85/105), these consumables fit seamlessly, thanks to their precision press-fit and slip-on connections. The standardized cylindrical shape and fixed dimensions make replacements straightforward, minimizing downtime during routine maintenance or after components show visible signs of wear.

Built for Industrial Environments

Constructed from high-conductivity copper alloy, these consumables thrive in demanding industrial settings. With a robust tensile strength of 350 MPa and a yield strength of 280 MPa, they handle continuous use and high cutting currents. Usable within a wide temperature range (-10C to 80C), they maintain integrity during extended operation.

FAQs of Hypertherm Consumables:

Q: How do I know when to replace Hypertherm consumables?

A: It is recommended to replace Hypertherm nozzles, electrodes, swirl rings, or retaining caps when you observe visible wear or after reaching the typical lifespan of 500 pierces. Regular inspection ensures optimal cutting quality and prevents equipment damage.Q: What models are these consumables compatible with?

A: These consumables are designed for use with Hypertherm Powermax 45, 65, 85, and 105 plasma cutting machines, ensuring a precise fit and seamless operation for industrial plasma cutting needs.Q: Where should I store Hypertherm consumables for longevity?

A: For maximum lifespan, keep the consumables in a dry, clean place, protected from humidity and contaminants. Proper storage preserves the nickel-plated surface and prevents premature oxidation or corrosion.Q: What are the key benefits of CNC machined and nickel-coated consumables?

A: CNC machining provides high dimensional accuracy (0.02 mm tolerance), ensuring consistent performance and fitting. The nickel coating enhances corrosion resistance, extending the service life of consumables even in harsh industrial environments.Q: How do I install these consumables in my plasma cutting machine?

A: The components feature a slip-on, non-threaded press-fit connection, making installation quick and tool-free. Simply fit the consumables into place following your machines specific guidelines for a precision seal.Q: What makes these consumables suitable for high-demand industrial cutting?

A: Their high-conductivity copper alloy material, robust mechanical properties, and ISO 9001-certified manufacturing process ensure reliable performance under continuous, rigorous operation. Withstand rated pressures of 6.5 bar and wide temperature variations for versatile industrial use.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Spare Parts Category

Thermal Dynamics Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Usage : Plasma Cutting

Yield Strength : Consistent

Section Shape : Other, Cylindrical

Kjellberg Plasma Consumables

Price Range 500.00 - 5000.00 INR / Bag

Minimum Order Quantity : 300 Bags

Usage : Plasma Cutting Machine

Yield Strength : High

Section Shape : Other, Cylindrical

Hypertherm Electrode

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Usage : Plasma Cutting Machine

Yield Strength : 70 MPa

Section Shape : Round

Thermal Dynamics Nozzle

Price 200 INR / Bag

Minimum Order Quantity : 300 Bags

Usage : Plasma Cutting Torch Consumable

Yield Strength : 70 MPa

Section Shape : Round

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry