Hypertherm Coolant

Hypertherm Coolant Specification

- Temperature Range

- Up to 60C (140F)

- Product Type

- Coolant Liquid

- Material

- Synthetic Fluid Blend

- Shape

- Liquid

- Standard

- Meets Hypertherm Plasma System Requirements

- Color

- Blue

- Usage

- Plasma Cutting System Cooling

- Application

- Thermal Management in Plasma Cutting Equipment

- Material Grade

- Premium Grade

- Non-Toxic

- Yes

- Freezing Point

- -37°C (-34°F)

- Compatibility

- For Use with Hypertherm Plasma Cutters and Systems

- Corrosion Inhibitor

- Yes

- Electrical Conductivity

- Low Conductivity

- Capacity

- 1 Gallon (3.78 Liters)

- pH Value

- 8.9

- Boiling Point

- 106°C (223°F)

- Shelf Life

- 5 Years (Unopened)

Hypertherm Coolant Trade Information

- Minimum Order Quantity

- 300 Bags

- FOB Port

- Navaseva

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- Gallens

- Main Domestic Market

- Himachal Pradesh, Pondicherry, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, East India, West India, Andaman and Nicobar Islands, Assam, Arunachal Pradesh, Bihar, Chandigarh, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttar Pradesh, Delhi, Gujarat, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

- Certifications

- ISO 9001

About Hypertherm Coolant

| Grade | PLASMA CUTTING MACHINE COOLANT |

| Color | PINK / WHITE / GREEN /ETC |

| Physical State | LIQUID |

| Pack Size | AS PER STD OR REQ |

| Packaging Type | Barrel |

| Model | Suitable With All Machine |

We offer Coolant suitable for hypertherm power sources.

Features

- The cooling system is built into the power supply for added convenience

- Liquid cooling contributes to long consumable parts life and low operating costs

- torch coolant protects from freezing to +10 deg F

MOQ: 5 Litre

Hypertherm Coolant Suitable for

HPR130

HPR260

HPR130XD

HPR260XD

HPR400XD

HPRMAX200

MAXPRO200

HSD

Engineered for Hypertherm Plasma Systems

This coolant formulation is specifically tailored to meet the rigorous requirements of Hypertherm plasma cutters and thermal management systems. Its low conductivity properties help prevent electrical faults during operation, while corrosion inhibitors safeguard internal components, ensuring longevity and consistent performance for industrial manufacturing environments.

Premium Cooling Performance and Protection

The synthetic blend delivers reliable cooling even at temperatures up to 60C (140F) by maintaining its fluid properties without breaking down. The advanced formulation also features a high boiling point of 106C (223F) and an impressive freezing threshold of -37C (-34F), ensuring uninterrupted operation across a broad range of climates. Its non-toxic and blue-colored solution makes handling and maintenance straightforward and safe.

FAQs of Hypertherm Coolant:

Q: How should Hypertherm Coolant be used in plasma cutting systems?

A: Pour the coolant directly into your plasma cutting equipments designated reservoir, ensuring system compatibility with Hypertherm plasma cutters. Avoid overfilling, and always check the manufacturers guidelines for proper handling and routine maintenance.Q: What are the benefits of using this Hypertherm Coolant?

A: This coolant offers enhanced thermal conductivity, effective corrosion inhibition, and long-term system protection. Its non-toxic, premium-grade formula extends equipment life, minimizes maintenance needs, and optimizes plasma cutter performance.Q: When is it time to replace Hypertherm Coolant in my equipment?

A: Replace the coolant as recommended in your plasma systems maintenance schedule or sooner if performance declines, fluid appears contaminated, or after five years if the original container is unopened.Q: Where can I source Hypertherm Coolant in India?

A: Hypertherm Coolant is available through authorized distributors, exporters, manufacturers, and suppliers across India. Contact your preferred industrial supplier or visit Hypertherms official network for genuine products.Q: What makes this coolant suitable for plasma cutting systems?

A: Its low electrical conductivity, premium material grade, and precise pH of 8.9 prevent scale, corrosion, and electrical issues. The coolant reliably supports thermal management, meeting Hypertherms stringent standards and safeguarding your investment.Q: Is there a specific process for disposing of used Hypertherm Coolant?

A: Yes, always follow local regulations and environmental guidelines when disposing of used coolant. Avoid releasing it into water sources, and consult your local waste management for eco-friendly disposal options.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Spare Parts Category

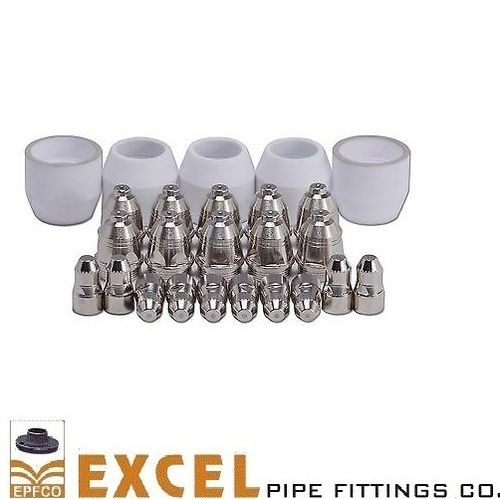

Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Color : Copper/Gold

Shape : Round

Product Type : Other, Plasma Consumables

Material : Other , Copper, Silver Plated

Esab Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Color : Copper, Silver, Metallic

Shape : Other, Cylindrical and Conical

Product Type : Other, Plasma Consumables

Material : Other , Copper, Silver Alloy, Hafnium

Plasma Spare Parts

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags, ,

Color : Copper, Silver, Gold, Black

Shape : Other, Cylindrical, Circular, Rectangular, Customized

Product Type : Other, Plasma Spare Parts

Material : Other , Copper, Brass, Ceramic, Stainless Steel

Panasonic Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Color : Copper Brown, White

Shape : Other, Round, Cylindrical

Product Type : Other, Plasma Consumables

Material : Other , Copper Alloy, Ceramic

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry