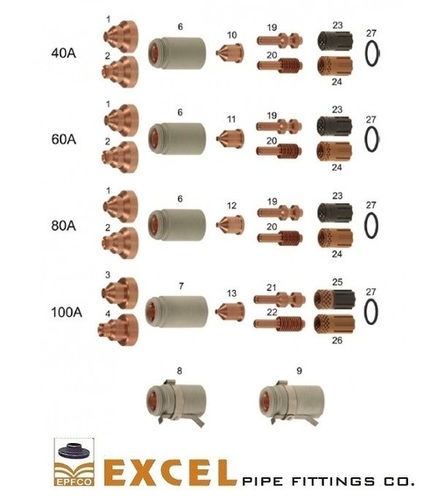

Plasma Torches

Plasma Torches Specification

- Tensile Strength

- 350 MPa

- Coating Type

- Nickel/Chrome

- Diameter

- 0.8 mm - 2.0 mm (orifice size)

- Sealing Type

- O-ring/Gasket

- Thread Type

- Fine/Coarse Thread

- Tolerance

- 0.02 mm

- Flexibility

- Rigid

- Temperature Range

- Up to 30,000C

- Yield Strength

- 200 MPa

- Connection Type

- Quick Connect/Threaded

- Product Type

- Plasma Torch

- Material

- Copper, Brass, Ceramic

- Connection

- Threaded/Plug Type

- Shape

- Cylindrical

- Standard

- ISO 9001

- Surface Treatment

- Nickel Plated

- Outer Diameter

- 20-35 mm

- Section Shape

- Round

- Length

- 150-220 mm

- Thickness

- 2-6 mm (tip body)

- Color

- Copper/Gold/Silver

- Usage

- Plasma Cutting & Welding

- Rated Pressure

- 5-7 Bar

- Material Grade

- High Conductivity Grade

- Application

- CNC Plasma Machines, Manual Plasma Cutting

Plasma Torches Trade Information

- Minimum Order Quantity

- 300 Bags

- FOB Port

- Navaseva

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- BOXES

- Main Domestic Market

- Himachal Pradesh, Manipur, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chhattisgarh, Chandigarh, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Lakshadweep, Maharashtra, Mizoram, Meghalaya, Nagaland, Odisha, Punjab, Pondicherry, Sikkim, Telangana, Tripura, West Bengal, Uttar Pradesh, Haryana, Tamil Nadu, Madhya Pradesh, Rajasthan, Central India, West India, All India

- Certifications

- ISO 9001

About Plasma Torches

| Model | As per requirement |

| Torch Type | Cutting torch |

| Fuel Gas Type | LPG, as per std / customize / requirement as per std / customize / requirement, Oxy-Acetylene, Hydrogen |

| Color | as per std / customize / requirement |

| Brand | As per specification |

| Max Flame Temperature | as per std / customize / requirement |

| Cutting Thickness (mm) | as per std / customize / requirement |

Manufacturer of a wide range of products which include thermal dynamics hand torch, thermal dynamics machine torch, hypertherm hand torch, hypertherm machine torch, kjellberg plasma hand torch and kjellberg mechanized plasma torch.

Versatility & Robust Performance

Engineered to meet rigorous demands, these plasma torches excel across a wide current range (20A200A) and operate effectively under varying conditions, from standard manual tasks to precision CNC cutting. They accommodate a variety of compatible consumables and work with input gases such as compressed air, nitrogen, or argon, making them suitable for diverse industrial applications.

Superior Build Quality & Ergonomics

Crafted from high-conductivity copper, durable brass, and resilient ceramic, these torches also feature nickel or chrome plating for enhanced corrosion resistance. Their ergonomic handles, constructed from heat-resistant plastic, ensure safe and comfortable use, while the designs cylindrical shape and standardized connections streamline setup and maintenance.

FAQs of Plasma Torches:

Q: How do I select between air cooled and water cooled plasma torches for my application?

A: Choosing between air cooled and water cooled plasma torches depends on your cutting duration and intensity. For lighter or intermittent cutting, air cooled torches are sufficient. For heavy-duty, extended cutting sessions or when working near the upper current range (above 100A), water cooled models offer better heat management and prolonged component life.Q: What types of consumables are compatible with PT-31, LGK-40, and AG-60 models?

A: These torch models use standard consumables such as electrodes, tips (nozzles), shields, and swirl rings. The consumables are generally interchangeable among compatible models, but it is important to select parts with matching orifice size, threading, and material grade for optimal performance.Q: When should I replace the torch consumables for the best cutting results?

A: Replace consumables like electrodes and nozzles when you notice reduced cut quality, increased dross, irregular arc, or visible wear. Frequent inspection will help maintain precise cuts, especially when using swirl or precision cut nozzles in demanding applications.Q: Where can these plasma torches be used and what machinery are they compatible with?

A: These torches fit most plasma cutting machines, including prominent CNC plasma systems and manual plasma cutters. They are widely used in metal workshops, manufacturing plants, automotive repair, and fabrication industries, both in India and internationally.Q: What are the benefits of using high-frequency and contact start ignition methods?

A: High-frequency start offers effortless, non-contact arc initiation that is ideal for automated CNC applications, while contact start ensures reliable operation in manual settings. Both ignition types provide consistent arc initiation, enhancing cut quality and reducing downtime.Q: How do I maintain proper operation and safety when using these plasma torches?

A: Regularly check for tight connections, wear on consumables, and maintain a clean flow of input gas. Ensure the duty cycle is not exceeded and use the correct cooling method for your application. Adhering to these practices ensures efficient operation and operator safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Spare Parts Category

Hypertherm Nozzle

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Surface Treatment : Other, Electroplated

Shape : Other, Cylindrical

Material : Other , Copper Alloy

Hypertherm Consumables

Price 5000 INR / Bag

Minimum Order Quantity : 300 Bags

Surface Treatment : Other, Nickel Plated

Shape : Round

Material : Other , Copper Alloy

Thermal Dynamics Nozzle

Price 200 INR / Bag

Minimum Order Quantity : 300 Bags

Surface Treatment : Other, Nickel Plated

Shape : Other, Cylindrical

Material : Other , Copper Alloy

Plasma Spare Parts

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags, ,

Surface Treatment : Other, Nickel Plated, Polished, Coated

Shape : Other, Cylindrical, Circular, Rectangular, Customized

Material : Other , Copper, Brass, Ceramic, Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry