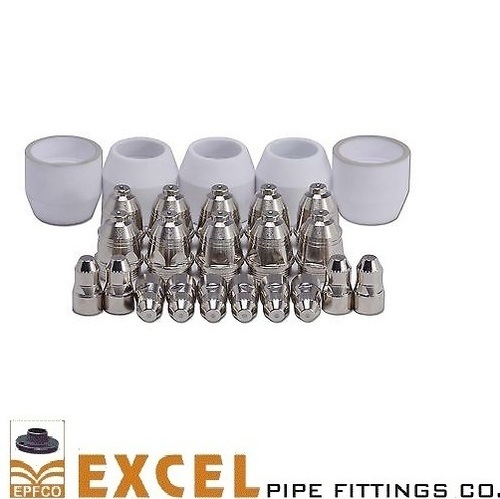

Thermal Dynamics Electrode

Price 1000 INR/ Bag

Thermal Dynamics Electrode Specification

- Tolerance

- 0.02 mm

- Flexibility

- Rigid

- Sealing Type

- Metal-to-Metal

- Connection Type

- Non-Threaded

- Yield Strength

- 85 MPa

- Coating Type

- Nickel Coated

- Diameter

- 1.6 mm

- Temperature Range

- Up to 400C

- Tensile Strength

- 210 MPa

- Product Type

- Electrode

- Material

- Copper Alloy

- Connection

- Push Fit

- Shape

- Cylindrical

- Standard

- ISO 6848

- Surface Treatment

- Nickel Plated

- Outer Diameter

- 6.4 mm

- Section Shape

- Round

- Length

- 60 mm

- Color

- Copper / Silver

- Usage

- Plasma Cutting Machines

- Material Grade

- High Conductivity Copper

- Application

- Plasma Cutting

Thermal Dynamics Electrode Trade Information

- Minimum Order Quantity

- 300 Bags

- FOB Port

- Navaseva

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- BOXES

- Main Domestic Market

- Dadra and Nagar Haveli, Chandigarh, Himachal Pradesh, Andaman and Nicobar Islands, Uttarakhand, Daman and Diu, Lakshadweep, Nagaland, South India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttar Pradesh, Delhi, Gujarat, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

- Certifications

- ISO 9001

About Thermal Dynamics Electrode

| Packaging | As per std / customize / requirement |

| Warranty | As per std / customize / requirement |

| Pieces Per Box | As per std / customize / requirement |

| Material | As per std / customize / requirement |

| Size | As per std / customize / requirement |

| Brand | Thermaldynamic |

| Model | As per std / customize / requirement |

Thermal Dynamics Plasma Consumables

SL60 Plasma Torch & Replacement Parts

- Thermal Dynamics Plasma Drag Tip 30 Amp 9-8206

- Thermal Dynamics Plasma Spare Parts Kit, Manual 1Torch

- Suitable for all Thermal Dynamics Cutmaster series plasma cutters.

SL100 Hand Torch (30-100A)

- Thermal Dynamics SureLok Electrode (Pack of 5) No. 9-8215

- Thermal Dynamics Start Cartridge No. 9-8213

- Thermal Dynamics Drag Tip Cutting 30 Amp (Pkg of 5) No. 9-8206

Engineered for Precision Plasma Cutting

This electrode stands out through its high conductivity copper alloy construction, nickel plating, and ISO 6848 standardization. Meticulously manufactured for compatibility with Thermal Dynamics plasma torches, it ensures minimal tolerance (0.02 mm) and offers a push-fit, non-threaded connection for secure assembly. The cylindrical, round-section shape and optimal dimensions provide outstanding electrical flow and fitting accuracy, making it ideal for demanding plasma cutting environments.

Exceptional Durability and Performance

Thanks to its robust nickel coating and high-grade copper material, the 9-8215 electrode delivers a high cycle life under rigorous conditions. With a tensile strength of 210 MPa and a yield strength of 85 MPa, it withstands significant operational stresses. The electrodes rigid design, metal-to-metal sealing, and up to 60A current capacity enable extended periods of efficient cutting without frequent replacements.

FAQs of Thermal Dynamics Electrode:

Q: How do I properly install the Thermal Dynamics Electrode (9-8215) in my plasma torch?

A: To install the 9-8215 electrode, ensure your plasma torch is powered off and fully cooled. Insert the electrode into the torch head using the push-fit connection; no threading is required. Confirm it sits securely to establish reliable electrical and mechanical contact.Q: What benefits does the nickel-plated, high conductivity copper alloy provide?

A: The nickel plating combined with high conductivity copper alloy ensures superior electrical performance, enhanced corrosion resistance, and increased operational lifespan, resulting in efficient, reliable plasma cutting and less frequent electrode replacements.Q: When should I replace the 9-8215 electrode in my plasma cutter?

A: Replace the electrode when you notice diminished cut quality or increased arc instability. The replacement cycle varies depending on usage intensity, cutting current, and material type, but this electrode is designed for high cycle life to reduce downtime.Q: Where should I store these electrodes to maintain peak performance?

A: For optimal life and performance, store the electrodes in a cool, dry environment away from sources of moisture. Proper storage prevents corrosion and surface degradation, ensuring consistent conductivity.Q: What is the process for determining compatibility with my plasma machine?

A: Verify your plasma torch is compatible with Thermal Dynamics parts and supports a push-fit, non-threaded cylindrical electrode with a 6.4 mm diameter and 60 mm length. Refer to your torchs manual or consult your distributor for confirmation.Q: How does the electrodes design contribute to precise plasma cutting?

A: The cylindrical, ISO 6848 standardized design, tight tolerance (0.02 mm), and metal-to-metal sealing enable stable, precise arc formation, ensuring clean, consistent cuts across a wide range of plasma cutting applications.Q: What are the main advantages of sourcing these electrodes from a manufacturer, distributor, or supplier in India?

A: Sourcing from established entities in India ensures access to high-quality, rigorously tested electrodes at competitive prices, supported by responsive local service and expertise for optimal plasma cutting performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Spare Parts Category

Thermal Dynamics Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Color : Copper/Silver

Temperature Range : High Temperature Resistant

Standard : Other, OEM Compatible

Product Type : Other, Plasma Consumables

Messer Oxyfuel Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Color : Copper, Golden

Temperature Range : 20C to 400C

Standard : Other, OEM Standard

Product Type : Other, Oxyfuel Consumables

Thermal Dynamics Nozzle

Minimum Order Quantity : 300 Bags

Color : Copper / Silver

Temperature Range : 20C to 250C

Standard : Other, ANSI/ISO Standard

Product Type : Other, Plasma Cutting Nozzle

Hypertherm Electrode

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Color : Copper

Temperature Range : Up to 500C

Standard : Other, ISO Certified

Product Type : Other, Electrode

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry