Koike Plasma Consumables

Price 300 INR/ Bag

Koike Plasma Consumables Specification

- Tolerance

- High Precision

- Connection Type

- Insert Type

- Temperature Range

- Up to 500C

- Diameter

- Varies (as per model)

- Flexibility

- Rigid

- Coating Type

- Plated Finish

- Yield Strength

- High

- Sealing Type

- Precise Fit

- Tensile Strength

- High

- Product Type

- Plasma Consumables

- Material

- Copper Alloy

- Connection

- Press Fit

- Shape

- Round

- Standard

- OEM Compatible

- Surface Treatment

- Plated

- Outer Diameter

- Varies (as per part number)

- Section Shape

- Cylindrical

- Length

- Custom / As per design

- Thickness

- Standard

- Color

- Copper / Brass

- Usage

- Industrial Cutting

- Application

- Plasma Cutting Machine

- Material Grade

- Premium Industrial Grade

- Replacement Cycle

- Depends on Usage Intensity

- Storage Condition

- Dry, Room Temperature

- Lifespan

- Long Service Life

- Compatible Brand

- Koike

- Consumable Type

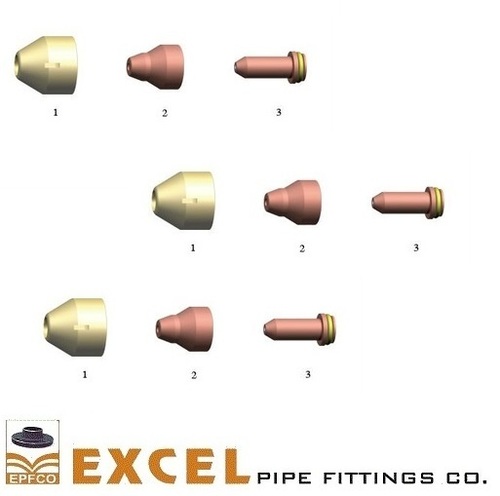

- Nozzles, Electrodes, Swirl Rings, Shields

- Part No.

- Various (as per Koike specification)

- Packaging Type

- Box

Koike Plasma Consumables Trade Information

- Minimum Order Quantity

- 300 Bags

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

About Koike Plasma Consumables

| Brand | KOIKE |

| Usage/Application | as per std / customize / requirement |

| Torch Type | Cutting torch |

| Max Flame Temperature (degree Celsius) | as per std / customize / requirement |

| Consumable Type | Electrodes, Spare Part, Torch |

| Cutting Capacity (mm) | as per std / customize / requirement |

| Weight (kg) | as per std / customize / requirement |

We have a complete range of Koike Plasma Consumables.KOIKE ELECTRODE , SHIELD , CAP , NOZZLE , COOLANT AVAILABLE

Engineered for Longevity and Precision

Koike Plasma Consumables utilize premium copper alloy materials with a plated finish, providing outstanding durability and resistance to heat up to 500C. These consumables are built to withstand high-intensity usage, ensuring long service life. Their compatibility with OEM standards and a precise press-fit connection make them an ideal choice for industrial users expecting consistent performance and minimal downtime.

Versatility in Application and Part Selection

Available in a variety of part numbers, shapes, and dimensions, Koike Plasma Consumables are specifically tailored to fit a range of plasma cutting machines. This adaptability allows users to select the ideal consumable for their equipment and cutting requirement, supporting diverse industrial tasks while ensuring a secure and efficient operation every time.

FAQs of Koike Plasma Consumables:

Q: How do I determine when to replace my Koike plasma consumables?

A: Replacement intervals for Koike plasma consumables depend primarily on the intensity and frequency of usage. Regular visual inspections for wear or changes in cut quality are recommended. If you notice inconsistent arc stability or poor cut quality, it may be time to replace the nozzles, electrodes, or other components.Q: What materials are used in Koike plasma consumables, and how does this affect performance?

A: These consumables are constructed from high-grade copper alloy and other premium materials, delivering excellent electrical conductivity and durability. The choice of materials, along with a plated surface treatment, contributes to precise cuts and longer service life, even under high-temperature industrial cutting conditions.Q: Where should I store Koike plasma consumables to maintain their quality?

A: To preserve the integrity and effectiveness of Koike plasma consumables, store them in a dry, room temperature environment. This prevents potential oxidation or corrosion, ensuring the consumables maintain high precision and remain ready for use when needed.Q: What are the benefits of using OEM compatible Koike plasma consumables?

A: OEM compatibility ensures that each consumable meets stringent manufacturer specifications, providing a reliable fit and optimal performance. This reduces downtime, enhances cut quality, and extends the lifespan of your plasma cutting equipment.Q: How do I install Koike plasma consumables onto my machine?

A: Installation follows a simple press-fit or insert-type process, corresponding to your particular machines design. Always consult your Koike machines manual or reach out to your supplier for detailed, model-specific instructions. Proper installation is crucial to ensure safe and precise operation.Q: What makes Koike plasma consumables suitable for heavy industrial usage?

A: Designed with high tensile and yield strength, coupled with precise fit and robust material grade, Koike consumables handle demanding plasma cutting operations. Their long service life and high-precision manufacturing minimize interruptions, making them ideal for intensive industrial workflows.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Spare Parts Category

Kjellberg Plasma Consumables

Price Range 500.00 - 5000.00 INR / Bag

Minimum Order Quantity : 300 Bags

Color : Copper/Bronze

Standard : Other, OEM/Compatible with Kjellberg

Product Type : Other, Plasma Consumables

Plasma Torches

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Color : Copper/Gold/Silver

Standard : Other, ISO 9001

Product Type : Other, Plasma Torch

Thermal Dynamics Electrode

Price 1000 INR / Bag

Minimum Order Quantity : 300 Bags

Color : Copper / Silver

Standard : Other, ISO 6848

Product Type : Other, Electrode

Plasma Spare Parts

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags, ,

Color : Copper, Silver, Gold, Black

Standard : Other, ISO 9001:2015

Product Type : Other, Plasma Spare Parts

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry