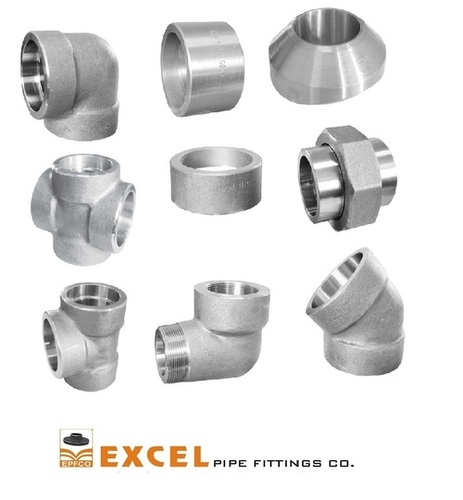

Inconel Forge Fittings

Price 250 INR/ Piece

Inconel Forge Fittings Specification

- Product Type

- Forge Fittings

- Material

- Inconel

- Type

- Elbow, Tee, Coupling, Union, Cross, Cap, Plug

- Technics

- Forged

- Shape

- Round, Hexagonal (as per fitting type)

- Connection

- Socket Weld, Threaded

- Standard

- ASTM B564 / ASME SB564

- Finishing

- Polished

- Surface Treatment

- Pickled, Passivated

- Size

- 1/8 NB to 4 NB

- Grade

- Inconel 600, 601, 625, 718, 800, 825

- Diameter

- Custom as per fitting size

- Thickness

- Sch 10s, Sch 40s, Sch 80s, Sch 160, XXS and custom

- Pressure Rating

- Class 2000, 3000, 6000, 9000 LBS

- Corrosion Resistance

- Excellent against acids and alkalis

- Application

- Petrochemical, Chemical, Oil & Gas, Aerospace, Power Generation

- Color

- Silver Grey

- Density

- 8.47 g/cm³ (Inconel 625)

- Hardness

- As per ASTM & customer requirements

- Packaging

- Wooden cases or as required

- Temperature Range

- up to 1100°C (as per grade)

- Thread Type

- NPT, BSP, BSPT

Inconel Forge Fittings Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Inconel Forge Fittings

| INCONEL | NICKEL ALLOY |

| Color | COPPER NICKEL |

| Thread Size | AS SPEC / REQ |

| Diameter | AS SPEC / REQ |

| Pressure | AS SPEC / REQ |

| Grade | INCONEL ALLOYS |

Inconel Forged Pipefittings

NB to 4; NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Type

Socket Weld (S/W) & Screwed (SCRD)

Form

Elbow 45 deg & 90 degree, Tee , Union, Full & Half coupling, Cross, Cap, Swage Nipple, Plug, Bush

Inconel Pipefittings

Standard : ASTM / ASME SB 336 / ASTM / ASME SB 564 / 160 / 472

Grade

- Inconel K600 Pipefittings / UNS N06600

- Inconel 601 Pipefittings / UNS N06601

- Inconel 625 Pipefittings / UNS N06625

- Inconel 800 Pipefittings / UNS N08800

- Inconel 800H Pipefittings / UNS N08810

- Inconel 825 Pipefittings / UNS N08825

Other

Customised Fittings

Test Certificate

Manufacturer Test Certificate as per EN 10204 / 3.1

Outstanding Durability for Extreme Conditions

Inconel forge fittings are meticulously engineered to withstand extreme temperatures and high pressures, making them indispensable in sectors where reliability is crucial. Their unparalleled resistance to corrosion and chemicals allows for prolonged usage in harsh environments, ensuring operational safety and long service life.

Versatile Range of Sizes and Configurations

Available in a spectrum of sizes from 1/8 NB to 4 NB and in forms such as elbows, tees, couplings, and more, Inconel fittings offer tailored solutions to meet varied industry requirements. Custom diameters and thicknesses further enhance their applicability across diverse projects.

Precision Engineering and Flexible Connections

These fittings are produced through advanced forging techniques, resulting in prestigious round or hexagonal shapes and options for socket weld or threaded (NPT, BSP, BSPT) connections. Each piece is finished to exacting standards and packed securely for worldwide distribution.

FAQs of Inconel Forge Fittings:

Q: How are Inconel forge fittings used in industries like petrochemical and aerospace?

A: Inconel forge fittings provide secure and leak-proof connections in piping systems that encounter extreme temperatures and corrosive substances. Their strength and resistance make them ideal for use in oil & gas pipelines, chemical plants, refineries, and aerospace components requiring robust, reliable connections.Q: What pressure and temperature ratings do these Inconel fittings support?

A: These fittings are rated for pressures from Class 2000 to 9000 LBS and can operate at temperatures up to 1100C, depending on the chosen Inconel grade. Such ratings make them suitable for both high-pressure and high-temperature environments.Q: When should I choose Inconel over other materials for forge fittings?

A: Select Inconel when facing highly corrosive environments or severe mechanical stressessuch as chemical processing, offshore drilling, or power generationwhere standard alloys might fail due to corrosion or heat.Q: Where are these Inconel fittings typically installed?

A: They are commonly used in facilities like oil refineries, gas processing units, power plants, chemical factories, and aerospace assembly lines, wherever reliable, corrosion-resistant connections are crucial.Q: What is the process for manufacturing these forge fittings?

A: Manufacturing involves forging high-purity Inconel alloys into specified shapes, finishing with processes like pickling or passivation, and then threading or shaping for socket weld connections according to ASTM B564/ASME SB564 standards.Q: What benefits do Inconel forge fittings offer compared to conventional steel fittings?

A: Inconel fittings provide superior resistance to corrosion, oxidation, and high temperatures, which ensures fewer maintenance requirements, increased safety, and prolonged lifespan, especially in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Forged Fittings Category

Threadolet

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other, Antirust Coated

Shape : Round

Thickness : As per standard or customer requirement

Diameter : Varies per size

Monel Forged Fittings

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other, Pickled, Passivated

Shape : Other, Tee, Elbow, Coupling, Union, Cap, Plug

Thickness : Sch 10 to Sch XXS

Diameter : Custom as per requirement

Screwed Fitting

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other, Anticorrosive Coated

Shape : Other, Elbow, Tee, Coupling, Union, Plug (as per requirement)

Thickness : 3 mm to 8 mm

Diameter : As per size selected

Stainless Steel Forge Fittings

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other, Pickled, Passivated

Shape : Other, Round, Square, Rectangular

Thickness : SCH 10S, 40S, 80S, 160S, XXS

Diameter : Customizable as per application

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry