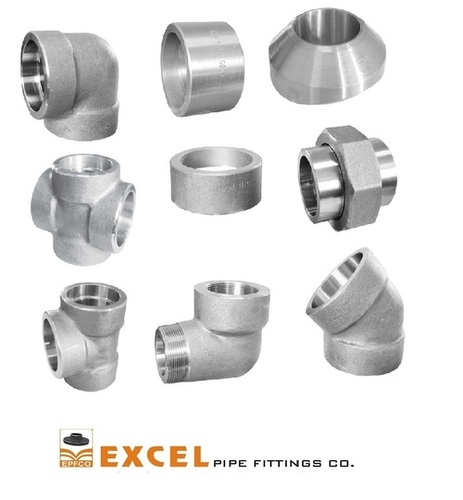

Stainless Steel Forge Fittings

Price 250 INR/ Piece

Stainless Steel Forge Fittings Specification

- Product Type

- Forge Fittings

- Material

- Stainless Steel

- Type

- Elbow, Tee, Coupling, Union, Cap, Plug, Cross, Nipple

- Technics

- Forged

- Shape

- Round, Square, Rectangular

- Connection

- Threaded, Socket Weld

- Standard

- ASTM A182, ASME B16.11, MSS-SP-83

- Finishing

- Polished, Bright, Black

- Surface Treatment

- Pickled, Passivated

- Size

- 1/8 NB to 4 NB

- Grade

- 304, 304L, 316, 316L, 321, 347, 310, 317L, 904L

- Diameter

- Customizable as per application

- Thickness

- SCH 10S, 40S, 80S, 160S, XXS

Stainless Steel Forge Fittings Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Stainless Steel Forge Fittings

| Connection | Male, Welded, Flange, Female |

| Material Grade | SS304L, ASTM A240, SS316, SS316L, SS304 |

| Schedule | as per std / customize / requirement |

| Weight | as per std / customize / requirement |

| Standard | as per std / customize / requirement |

| Size | 1/2", 1", 3", 3/4", 2", as per std / customize / requirement |

| Application | Gas Pipe, Chemical Fertilizer Pipe, Hydraulic Pipe, Structure Pipe |

Stainless Steel Forged Pipe fittings

Specification:

- RangeForged Fittings

NB to 4 NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75. - Type - Socket Weld (S/W) & Screwed (SCRD)

- Form - Elbow 45 deg & 90 degree, Tee , Union, Full & Half coupling, Cross, Cap, Swage Nipple, Plug, Bush

- Stainless Steel Butt Weld Fittings

- Standard : ASTM / ASME A/SA 403 GR WP "S" "W" " WX"

- Grade : 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L

- Standard : ASTM / ASME A/SA 182

- Grade : F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L

Other

- Dairy Fittings

- Customised Fittings

TEST CERTIFICATE

Manufacturer Test Certificate as per EN 10204 / 3.1

Trusted Performance for Critical Industries

Our stainless steel forge fittings are tailored for sectors where safety and durability are paramount, such as petrochemical plants, oil & gas infrastructure, chemical processing, power generation, and marine construction. The fittings outstanding corrosion resistance and strength make them a dependable choice, even in aggressive and high-pressure environments.

Precision Engineering and Versatile Options

We offer a comprehensive selection of fitting typesincluding elbows, tees, unions, couplings, and morealong with customizable diameters, thicknesses, and end connections (BSP, NPT, SW) to meet diverse technical specifications. Manufactured under strict standards like ASTM A182 and ASME B16.11, our fittings guarantee precise performance and seamless compatibility.

Quality Manufacturing and Impeccable Finishing

Forged using advanced hot-working techniques and subjected to rigorous heat treatment (solution annealing), our fittings achieve superior mechanical properties and finishing options such as polished, bright, or black surfaces. Each piece undergoes passivation and pickling to ensure longevity and optimal surface integrity, making them suitable for global export in secure packaging.

FAQs of Stainless Steel Forge Fittings:

Q: How are stainless steel forge fittings manufactured?

A: Stainless steel forge fittings are produced through a hot forging process, followed by solution annealing. This method enhances their mechanical strength and provides exceptional durability and corrosion resistance, which is vital for use in demanding environments.Q: What industries commonly use these stainless steel forge fittings?

A: These fittings are widely used in petrochemical, oil & gas, chemical, power generation, shipbuilding, and construction industries due to their robust performance under high pressure and extreme temperatures.Q: When should forged fittings be chosen over other connection types?

A: Forged fittings are ideal when the application demands higher pressure and temperature ratings, as well as superior mechanical strength. Their reliability makes them preferable in critical systems where leaks or failures can have significant consequences.Q: Where can these fittings be installed, given their temperature and pressure capabilities?

A: These fittings are suitable for locations where temperatures range from -29C up to 593C and working pressures reach 9000 PSI, such as high-stress piping systems in refineries, power plants, or off-shore platforms.Q: What are the benefits of solution annealing in the manufacturing process?

A: Solution annealing relieves internal stresses, improves toughness, and restores corrosion resistance to the stainless steel, resulting in fittings that are highly durable and long-lasting, even in corrosive or high-temperature environments.Q: How does the choice of end connection (BSP, NPT, SW) affect fitting usage?

A: The type of end connection ensures compatibility with existing piping systems. BSP and NPT are standard threaded connections, offering ease of installation, while socket weld connections provide higher integrity and strength for welded joins.Q: What packaging options are available for export?

A: Our fittings are packed in export-worthy wooden boxes, cartons, or as per specific requirements. This careful packaging protects against corrosion and mechanical damage during transportation, ensuring products arrive in optimal condition.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Forged Fittings Category

Monel Forged Fittings

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Technics : Other, Forged

Shape : Other, Tee, Elbow, Coupling, Union, Cap, Plug

Product Type : Other, Forged Fittings

Size : 1/8 NB to 4 NB

Elbolet

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Technics : Other, Forged

Shape : Other, Elbow Branch Connection

Product Type : Other, Elbolet

Size : 1/2 to 24 (DN15 to DN600)

Inconel Forge Fittings

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Technics : Other, Forged

Shape : Other, Round, Hexagonal (as per fitting type)

Product Type : Other, Forge Fittings

Size : 1/8 NB to 4 NB

Threadolet

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Technics : Other, Forged

Shape : Round

Product Type : Other, Threadolet

Size : 1/8 to 4 (DN6 to DN100)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry