Screwed Fitting

Price 250 INR/ Piece

Screwed Fitting Specification

- Product Type

- Screwed Fitting

- Material

- Stainless Steel

- Type

- Pipe Fitting

- Technics

- Forged

- Shape

- Elbow, Tee, Coupling, Union, Plug (as per requirement)

- Connection

- Female Threaded

- Standard

- ANSI, DIN, JIS, BS

- Finishing

- Polished

- Surface Treatment

- Anti-corrosive Coated

- Size

- 1/8 to 4 (DN6 to DN100)

- Grade

- SS304, SS316, SS316L

- Diameter

- As per size selected

- Thickness

- 3 mm to 8 mm

- Color

- Silver

- Pressure Rating

- 150 lbs, 3000 lbs, 6000 lbs

- Rust Resistance

- Yes

- Customisation

- Available as per order

- Application

- Industrial, Plumbing, Oil & Gas, Chemical

- Thread Type

- BSP, NPT, BSPT

- Packaging Type

- Carton Box/Pallet

- Temperature Range

- -20°C to 220°C

Screwed Fitting Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Screwed Fitting

| Brand | as per requirement /specification |

| Thread Size | as per requirement /specification |

| Size | 1/2 inch, 3/4 inch, 1 inch, 2 inch, 3 inch |

| Material | as per requirement /specification |

| Application | Structure Pipe, Gas Pipe, Hydraulic Pipe, Chemical Fertilizer Pipe, Pneumatic Connections |

| QTY | as per requirement /specification |

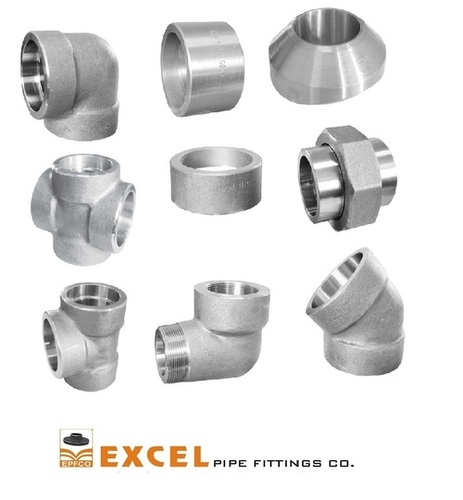

Screwed fittings

Range Forged Fittings

NB to 4" NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Type

Socket Weld (S/W) & Screwed (SCRD)

Form

Elbow 45 deg & 90 degree, Tee , Union, Full & Half coupling, Cross, Cap, Swage Nipple, Plug, Bush

TEST CERTIFICATE

Manufacturer Test Certificate as per EN 10204 / 3.1

Stainless Steel Forged for Strength

Each fitting is manufactured utilizing advanced forging techniques, delivering impressive mechanical strength and longevity. The anti-corrosive surface treatment ensures the fittings perform reliably even in aggressive environments, further reinforced by the use of high-grade stainless materials like SS304, SS316, and SS316L.

Diverse Applications and Custom Options

Engineered for sector-wide compatibility, our range serves industrial, plumbing, oil and gas, and chemical processing needs. With a selection of thread types, shapes, and pressure ratings, every fitting can also be tailored to meet unique specifications, making them versatile for both standard and highly technical operations.

Compliance with Global Standards

All fittings adhere to renowned international standards including ANSI, DIN, JIS, and BS. This compliance guarantees safe integration with various piping systems worldwide, providing confidence to manufacturers, distributors, and end-users alike. Each fitting is meticulously inspected and packaged for safe delivery.

FAQs of Screwed Fitting:

Q: How do I determine the correct thread type and pressure rating for my piping system?

A: Identify the connection standard in your system, whether BSP, NPT, or BSPT, and consult your applications pressure requirements to select from 150 lbs, 3000 lbs, or 6000 lbs ratings. Our technical team can help assess your specifications for an optimal match.Q: What materials are used to manufacture these screwed fittings?

A: The fittings are forged from high-quality stainless steel grades, specifically SS304, SS316, and SS316L. These materials are chosen for their excellent corrosion resistance and reliability in harsh environments.Q: When should I opt for customization instead of standard fittings?

A: Customization is ideal when your operation demands unique shapes, sizes, or threading not covered by standard offerings. Common reasons include special installation dimensions or specific industry compliance requirements.Q: Where can these screwed fittings be applied?

A: Our fittings are suitable for use in industrial systems, plumbing installations, oil and gas pipelines, and chemical processing. Their robust construction and resistance to corrosion make them appropriate for both indoor and outdoor applications.Q: What is the process for ordering and receiving these fittings?

A: Simply submit your specifications or select from our catalog. Each order is packed in protective carton boxes or pallets and is shipped according to your location. Well provide lead times and shipping details upon confirmation.Q: How does the anti-corrosive coating benefit the fittings lifespan?

A: The anti-corrosive coating protects the stainless steel from rust and chemical degradation, significantly prolonging operational life and reducing maintenance in corrosive or demanding environments.Q: What usage advantages do forged stainless steel fittings offer compared to cast alternatives?

A: Forged fittings offer superior mechanical strength and uniformity, reducing leak risks and ensuring better performance under pressure. This makes them more reliable than cast fittings, especially for rigorous industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Forged Fittings Category

Outlets

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Diameter : Customizable

Shape : Round

Technics : Other, Forged

Surface Treatment : Galvanized

Inconel Forge Fittings

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Diameter : Custom as per fitting size

Shape : Other, Round, Hexagonal (as per fitting type)

Technics : Other, Forged

Surface Treatment : Other, Pickled, Passivated

Monel Forged Fittings

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Diameter : Custom as per requirement

Shape : Other, Tee, Elbow, Coupling, Union, Cap, Plug

Technics : Other, Forged

Surface Treatment : Other, Pickled, Passivated

High Pressure Fittings

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Diameter : Custom as per design

Shape : Other, Round / Hexagonal / As per Drawing

Technics : Other, Forged / Machined

Surface Treatment : Other, Passivated, ElectroPolished

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry