Hypertherm Electrode

Hypertherm Electrode Specification

- Temperature Range

- Up to 500C

- Tolerance

- 0.05 mm

- Connection Type

- Threaded

- Tensile Strength

- 200 MPa

- Coating Type

- Electrolytic

- Bend Radius

- Not Flexible

- Yield Strength

- 70 MPa

- Diameter

- 1.5 mm

- Thread Type

- Metric

- Flexibility

- Rigid

- Product Type

- Electrode

- Material

- Copper

- Connection

- Direct Fit

- Shape

- Cylindrical

- Standard

- ISO Certified

- Surface Treatment

- Coated

- Outer Diameter

- 6.5 mm

- Section Shape

- Round

- Length

- 30 mm

- Thickness

- Standard

- Color

- Copper

- Usage

- Plasma Cutting Machine

- Rated Pressure

- Normal Atmospheric

- Application

- Metal Cutting

- Material Grade

- High Conductivity Copper

- Current Rating

- 40A to 85A

- Replacement Cycle

- As per machine maintenance schedule

- Electrode Life

- 1000+ starts

- Packaging Type

- Sealed Pack

- Resistance to Oxidation

- High

- Weight

- Approx. 12g per piece

- Compatible Models

- Hypertherm Powermax plasma systems

- Hardness

- 110 HB

- Storage Condition

- Dry, Room Temperature

Hypertherm Electrode Trade Information

- Minimum Order Quantity

- 300 Bags

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

About Hypertherm Electrode

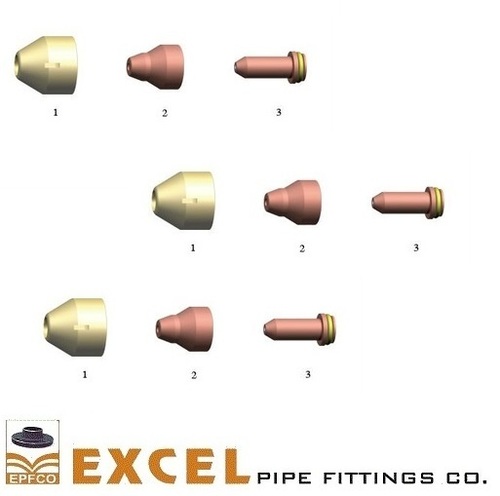

| Pieces Per Box | as per std / customize / requirement |

| Material | as per std / customize / requirement |

| Model | HYPERTHERM |

| Consumable Type | Electrodes |

| Power (W) | as per std / customize / requirement |

| Fitting | as per std / customize / requirement |

| Packaging Type | as per std / customize / requirement |

We are suppliers for Hypertherm consumables and machines. The above image is known as Electrode. Electrode is a spare pare of Hypertherm Plasma torch.

Precision in Plasma Cutting

Experience unmatched accuracy and performance with the Hypertherm Electrode. Manufactured from high-quality copper with a standard thickness and round section, this electrode maintains strict tolerances of 0.05 mm. Designed for compatibility with Hypertherm Powermax systems, it provides high oxidation resistance and steady current flow, ensuring superior cut quality and extended service life in plasma cutting processes.

Reliability for Industrial Demands

Built to endure tough conditions, this electrode features a surface electrolytic coating and is delivered in sealed packs for enhanced shelf life. Its rigid, direct-fit construction facilitates quick installation and seamless operation. Rated for currents ranging from 40A to 85A and designed to withstand repeated starts, this component is ideal for continuous use in demanding environments. Maintain optimal performance by following the recommended replacement cycle as per your machines maintenance schedule.

FAQs of Hypertherm Electrode:

Q: How do I install the Hypertherm Electrode in my plasma cutting machine?

A: Install the Hypertherm Electrode by threading it into the designated torch head slot on compatible Hypertherm Powermax plasma systems. Ensure the connection is secure and leak-free before starting the operation.Q: What maintenance or replacement schedule should I follow for this electrode?

A: Replace the electrode as recommended by your machines maintenance schedule or after reaching approximately 1000 starts to ensure consistent performance and prevent damage to other torch components.Q: Where should I store Hypertherm Electrodes to maintain their integrity?

A: Store the electrodes in a dry area at room temperature, preferably in their sealed packaging. Avoid exposure to moisture to prevent oxidation and maintain the longevity of the electrode.Q: What benefits does the high conductivity copper electrode offer for plasma cutting?

A: High conductivity copper significantly improves current flow, resulting in stable arcs, efficient material cut, and longer component life. The electrolytic coated surface further enhances oxidation resistance and operational reliability.Q: When should the electrode be replaced to ensure optimal plasma cutter performance?

A: You should replace the electrode when you notice a decline in cutting quality, increased wear after 1000+ starts, or as per your plasma cutters maintenance guidelines to maintain optimal results.Q: What applications are suitable for this electrode?

A: This electrode is optimized for metal cutting applications in plasma cutting machines using the Hypertherm Powermax system, supporting a current range of 40A to 85A and temperatures up to 500C.Q: How does the electrodes design support precise metal cutting?

A: The electrodes cylindrical, ISO-certified form with strict manufacturing tolerances ensures consistent and controlled plasma arcs, delivering clean, accurate cuts on a variety of metals.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Spare Parts Category

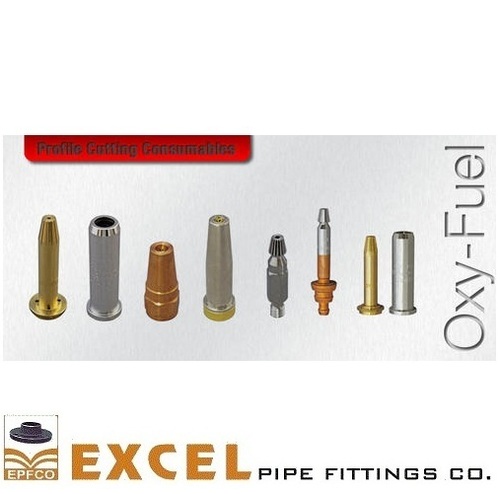

Oxy Fuel Consumables

Price Range 500.00 - 5000.00 INR / Bag

Minimum Order Quantity : 300 Bags

Material : Other , Copper Alloy / Brass

Shape : Other, Cylindrical / Conical

Standard : Other, IS, ISO, and DIN standards compatible

Thermal Dynamics Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Material : Other , Copper Alloy

Shape : Other, Round/Custom

Standard : Other, OEM Compatible

Kjellberg Plasma Consumables

Price Range 500.00 - 5000.00 INR / Bag

Minimum Order Quantity : 300 Bags

Material : Other , Copper Alloy

Shape : Other, Round/Varied

Standard : Other, OEM/Compatible with Kjellberg

Thermal Dynamics Nozzle

Price 200 INR / Bag

Minimum Order Quantity : 300 Bags

Material : Other , Copper Alloy

Shape : Other, Cylindrical

Standard : Other, ANSI/ISO Standard

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry