MACHINE Coolant

MACHINE Coolant Specification

- Temperature Range

- Up to 70C

- Product Type

- Coolant

- Material

- Water Soluble Oil

- Shape

- Liquid

- Standard

- Industrial Grade

- Color

- Green

- Usage

- For Cooling and Lubricating Machine Parts

- Application

- CNC Machines, Lathe Machines, Grinding, Drilling, Milling

- Material Grade

- High Performance

- Emulsification

- Stable

- Solubility

- Water Soluble

- Biodegradability

- Yes

- Flash Point

- Non-Flammable

- Odor

- Mild

- Foaming Tendency

- Low

- Storage Conditions

- Cool, Dry Place

- Form

- Concentrated Liquid

- Corrosion Resistance

- Excellent

- Packaging Size

- 5 L, 20 L, 50 L Cans

- Shelf Life

- 24 Months (Unopened)

- pH Value

- 8.5 - 9.2

MACHINE Coolant Trade Information

- Minimum Order Quantity

- 300 Bags

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

About MACHINE Coolant

| Grade | PLASMA CUTTING MACHINE COOLANT |

| Packaging Size | 3 / 5 / 10 / 50 / 100 LTR |

| Physical State | LIQUID |

| Brand | COOLANT FOR ALL PLASMA CUTTING |

| Usage/Application | PLASMA MACHINE |

| Pack Size (Litre) | 5/10/30/50/100 |

Features

- The cooling system is built into the power supply for added convenience

- Liquid cooling contributes to long consumable parts life and low operating costs

- torch coolant protects from freezing to +10 deg F

Industrial-Grade Cooling and Lubrication

Engineered as a water-soluble oil, this coolant is tailored for various industrial machines, including CNC, lathes, grinders, drills, and milling machines. Its stable emulsification ensures a consistent cooling and lubricating action, safeguarding machinery from heat and wear while providing superior corrosion protection. Suitable for demanding environments, it supports operational efficiency and extends machine lifespan.

Safety and Environmental Benefits

Designed with safety in mind, this coolant is non-flammable and possesses a mild odor, making it suitable for regular industrial use. Its biodegradable nature reflects modern environmental standards, helping facilities minimize ecological impact without sacrificing performance. The low-foaming property further enhances system reliability, reducing maintenance requirements.

Versatile Packaging and Easy Storage

Available in convenient 5 L, 20 L, and 50 L can sizes, the coolant can be efficiently stored and dispensed as needed. With a recommended shelf life of 24 months when kept unopened in a cool, dry place, it ensures reduced waste and cost-effective inventory management for distributors and manufacturers across India.

FAQs of MACHINE Coolant:

Q: How should I mix the concentrated coolant before use in machines?

A: Dilute the concentrated coolant with water according to the manufacturers recommended ratio, ensuring thorough mixing until the solution is uniform. Always use clean water and add the coolant to water, not the reverse, to achieve optimal emulsification.Q: What benefits does this coolant offer for CNC and lathe machines?

A: This coolant effectively cools and lubricates moving parts, minimizes wear and friction, provides excellent corrosion resistance, and ensures stable emulsificationall of which extend machine lifespan and enhance operational efficiency.Q: Where should I store the coolant to preserve its shelf life?

A: Store the coolant in an unopened container in a cool, dry place, away from direct sunlight or extreme heat. Proper storage conditions preserve its properties and ensure up to 24 months of shelf life.Q: Is the coolant safe to use in operations with high temperatures up to 70C?

A: Yes, this high-performance coolant is engineered for industrial applications and remains stable and effective at temperatures up to 70C, protecting machinery during intense operations.Q: What are the ecological advantages of using this product?

A: The coolant is biodegradable and non-flammable, making it safer for the environment and lowering health and safety risks for workers. This aligns with contemporary standards for sustainable industrial use.Q: When is it best to replace the coolant in the machine system?

A: Replace the coolant based on the machine manufacturers guidelines or when signs of contamination, reduced effectiveness, or changes in the coolants appearance or odor are observed. Regular monitoring prolongs both machine and coolant life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Spare Parts Category

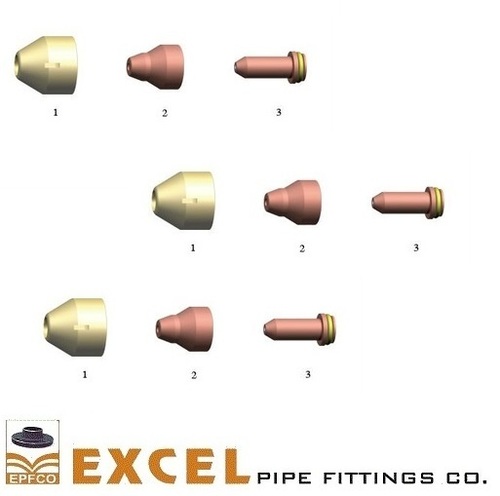

Kjellberg Plasma Consumables

Price Range 500.00 - 5000.00 INR / Bag

Minimum Order Quantity : 300 Bags

Standard : Other, OEM/Compatible with Kjellberg

Color : Copper/Bronze

Product Type : Other, Plasma Consumables

Thermal Dynamics Nozzle

Price 200 INR / Bag

Minimum Order Quantity : 300 Bags

Standard : Other, ANSI/ISO Standard

Color : Copper / Silver

Product Type : Other, Plasma Cutting Nozzle

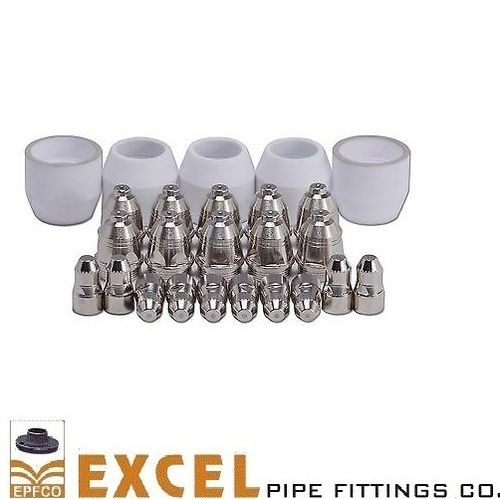

Panasonic Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Standard : Other, OEM Standard

Color : Copper Brown, White

Product Type : Other, Plasma Consumables

Ajan Plasma Consumables

Price 1000 INR / Bag

Minimum Order Quantity : 300 Bags

Standard : Other

Color : Copper Red

Product Type : Other

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry