Copper Forged fittings

Price 250 INR/ Piece

Copper Forged fittings Specification

- Product Type

- Copper Forged Fittings

- Material

- Copper

- Type

- Forged

- Technics

- Forging

- Shape

- Elbow, Tee, Coupling, Union, Reducer, Nipple, Hex Plug, Adapter, Cap

- Connection

- Threaded, Socket Weld

- Standard

- ASTM B62, ASME B16.11

- Finishing

- Polished, Bright Annealed

- Surface Treatment

- Cleaned, Anti-oxidation Coating

- Size

- 1/8 to 4 (NPS)

- Grade

- C12200, C11000

- Diameter

- As per specification / customer requirement

- Thickness

- As per standard or custom

- Hardness

- Soft / Annealed, Half Hard

- Inspection

- 100% Dimensional & Visual Inspection

- Manufacturing Process

- Hot Forged, Machined

- Color

- Copper Red

- Temperature Range

- -196°C to 400°C

- Corrosion Resistance

- Excellent

- Pressure Rating

- 2000LB, 3000LB, 6000LB

- Packaging

- Wooden Cases, Carton Boxes, Pallets

- Application

- Plumbing, Refrigeration, HVAC, Gas Fitting, Industrial Piping

- Test Certificates

- Available (EN 10204/3.1)

Copper Forged fittings Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Copper Forged fittings

| Connection | Flange, Male, Female, Welded |

| Size | 10 inch-20 inch, 2 inch-3 inch, >20 inch, 3 inch-10 inch, 1/4 inch-1 inch, 1 inch-2 inch |

| Application | Hydraulic Pipe, Structure Pipe, Gas Pipe, Chemical Fertilizer Pipe |

| Type | Ferrule, Swivel Nut, Adapters |

| Material | COPPER |

| Color | COPPER |

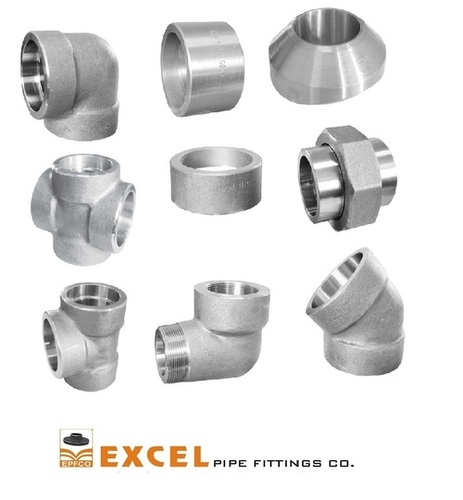

Copper Forged Pipe Fittings

Range

Forged Fittings : 1 NB to 4" NB in 3000 LBS, 6000 LBS, 9000 LBS

Outlet's : 1 to 24 in 3000 LBS, 6000 LBS, 9000 LBS

Type : Socket Weld (S/W) & Screwed (SCRD)

Form : Elbow 45 deg & 90 degree, Tee , Union, Full & Half coupling, Cross, Cap, Swage Nipple, Plug, Bush

Outlet's : Weldolet, Sockolet, Elbolet, Threadolet, Nipolet, Letrolet, Swepolet

Other Form :

Hydraulic Fitting

Instrumentation Fitting

Copper Pipe Fitting

Grade : De-oxidized & Electrolytic 99.9%

Test Certificate

Manufacturer Test Certificate as per EN 10204 / 3.1

Exceptional Corrosion Resistance

Copper Forged fittings are renowned for their excellent resistance to corrosion, making them ideal for environments exposed to moisture, chemicals, or varying temperatures. Their clean, anti-oxidation coated surfaces help extend service life, ensuring reliability in challenging applications.

Precision Manufacturing & Inspection

Each fitting undergoes a rigorous hot forging and machining process, followed by 100% dimensional and visual inspection. This guarantees compliance with international standards such as ASTM B62 and ASME B16.11, resulting in high-quality and consistent products tailored to specific customer requirements.

FAQs of Copper Forged fittings:

Q: How are Copper Forged fittings manufactured to meet high pressure and temperature ranges?

A: Copper Forged fittings are produced using a hot forging process, followed by machining and bright annealing, enabling them to withstand pressures up to 6000LB and temperatures from -196C to 400C. This robust manufacturing ensures strength, dimensional accuracy, and reliability.Q: What types of applications are suitable for these Copper Forged fittings?

A: These fittings are specifically designed for plumbing, refrigeration, HVAC, gas fitting, and a broad spectrum of industrial piping systems due to their corrosion resistance, pressure rating, and durability. Their versatility makes them suitable for both commercial and industrial use.Q: When should I use annealed versus half hard Copper Forged fittings?

A: Annealed (soft) fittings are preferable where flexibility and easier installation are required, while half hard fittings offer increased strength for systems subjected to higher mechanical stress. Choice depends on the specific mechanical and installation needs of your system.Q: Where can I source Copper Forged fittings in various shapes and sizes?

A: You can procure these fittings from reputable manufacturers, distributors, and exporters based in India. The products are available in several geometrieselbows, tees, couplings, reducers, and morewith size ranges from 1/8 to 4 NPS, matching diverse project requirements.Q: What is the benefit of the excellent corrosion resistance in copper fittings?

A: Outstanding corrosion resistance ensures a long service life in adverse conditions, minimizing maintenance needs and preventing system failures. This quality is crucial for installations in environments with high humidity, chemical exposure, or fluctuating temperatures.Q: How are the Copper Forged fittings packaged and certified before dispatch?

A: Fittings are securely packed in wooden cases, carton boxes, or on pallets to optimize protection during transit. Each batch is supplied with comprehensive test certificates (EN 10204/3.1), confirming compliance with material and manufacturing standards.Q: What standards and grades do these Copper Forged fittings adhere to?

A: These fittings comply with ASTM B62 and ASME B16.11 standards, and are available in copper grades C12200 and C11000. They are manufactured as per defined industry standards or according to specific customer requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Forged Fittings Category

Outlets

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Diameter : Customizable

Grade : SS304, SS316

Size : 1/2 Inch to 24 Inch

Standard : Other, ANSI / ASME / DIN / JIS / BS

Inconel Forge Fittings

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Diameter : Custom as per fitting size

Grade : Inconel 600, 601, 625, 718, 800, 825

Size : 1/8 NB to 4 NB

Standard : Other, ASTM B564 / ASME SB564

Monel Forged Fittings

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Diameter : Custom as per requirement

Grade : Monel 400, Monel K500

Size : 1/8 NB to 4 NB

Standard : Other, ASTM B564, ASME SB564

High Pressure Fittings

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Diameter : Custom as per design

Grade : SS304 / SS316 / SS316L

Size : 1/8 to 2 (Custom sizes available)

Standard : Other, ASTM / ASME / DIN / JIS

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry