Monel Forged Fittings

Price 250 INR/ Piece

Monel Forged Fittings Specification

- Product Type

- Forged Fittings

- Material

- Monel

- Type

- Socket Weld, Threaded

- Technics

- Forged

- Shape

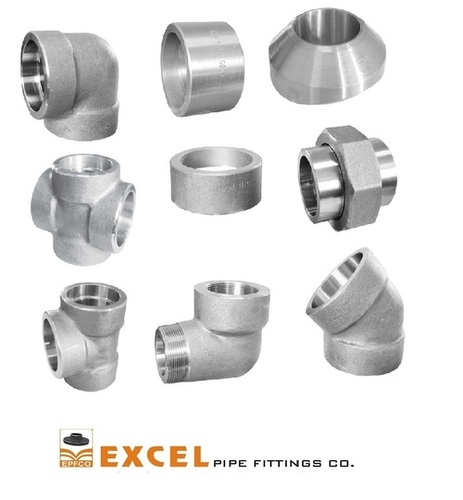

- Tee, Elbow, Coupling, Union, Cap, Plug

- Connection

- Screwed (Threaded), Socket Weld

- Standard

- ASTM B564, ASME SB564

- Finishing

- Smooth, Machined Finish

- Surface Treatment

- Pickled, Passivated

- Size

- 1/8 NB to 4 NB

- Grade

- Monel 400, Monel K500

- Diameter

- Custom as per requirement

- Thickness

- Sch 10 to Sch XXS

Monel Forged Fittings Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Monel Forged Fittings

| Brand | as per std / customize / requirement |

| Thread Size | as per std / customize / requirement |

| Material | as per std / customize / requirement |

| Standards | as per std / customize / requirement |

| Size | 3/4 inch, 1 inch, 3 inch, 2 inch, 1/2 inch |

| Application | Hydraulic Pipe, Pneumatic Connections, Structure Pipe, Gas Pipe, Chemical Fertilizer Pipe |

| Color | as per std / customize / requirement |

| Specification | as per std / customize / requirement |

| Standard | as per std / customize / requirement |

| Size/Diameter | as per std / customize / requirement |

| Grade | as per std / customize / requirement |

Monel Forged Pipe fittings

NB to 4" NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Type

Socket Weld (S/W) & Screwed (SCRD)

Form

Elbow 45 deg & 90 degree, Tee , Union, Full & Half coupling, Cross, Cap, Swage Nipple, Plug, Bush

Monel Pipefittings

Standard : ASTM / ASME SB 336 / ASTM / ASME SB 564 / 160 / 472

Grade

- Monel 400 Pipefittings / UNS N04400

- Monel K500 Pipefittings / UNS N05500

Other

Customised Fittings

Test Certificate

Manufacturer Test Certificate as per EN 10204 / 3.1

Exceptional Performance in Harsh Environments

Monel forged fittings stand out for their remarkable ability to perform reliably under extremes of temperature and pressure. The materials inherent corrosion resistance against seawater and acids makes it particularly suitable for marine and chemical environments. Whether used in the oil & gas industry or power generation facilities, these fittings maintain their integrity and strength even when exposed to aggressive media and fluctuating conditions.

Precision Manufacturing for Quality Assurance

Each fitting is produced using drop forged or closed die forged processes, ensuring superior mechanical properties and accurate dimensions. Strict adherence to ASTM B564 and ASME SB564 standards, along with comprehensive traceability through grade, size, heat number, and manufacturers logo markings, guarantees quality. Test certificates EN 10204 3.1/3.2 are provided for complete confidence in compliance and safety.

FAQs of Monel Forged Fittings:

Q: How are Monel forged fittings manufactured?

A: Monel forged fittings are produced using either drop forging or closed die forging processes. This method involves shaping heated Monel alloy under high pressure within precision dies, resulting in components that exhibit superior strength, durability, and consistent quality compared to other manufacturing techniques.Q: What applications are these Monel forged fittings suitable for?

A: These fittings are specifically designed for demanding sectors like oil & gas, petrochemical, marine, chemical processing, and power generation. Their exceptional resistance to corrosion and ability to withstand high pressures and temperatures make them ideal for use in harsh operating environments.Q: When should I choose Monel forged fittings over other materials?

A: Monel forged fittings should be chosen when the application requires excellent resistance to seawater, acids, and high-temperature operations. Their ability to maintain strength and resist corrosion in aggressive conditions gives them an edge over many conventional materials.Q: Where are Monel forged fittings commonly installed?

A: Monel forged fittings are widely installed in pipelines, pressure vessels, and processing equipment within refineries, offshore rigs, marine vessels, power stations, and chemical plantsany setting where durability and high corrosion resistance are critical.Q: What benefits do Monel forged fittings offer for system reliability?

A: They provide long-term operational reliability due to their high mechanical strength, impressive corrosion resistance, robust sealing capabilities, and ability to perform in extreme temperatures from -196C to 815C. This reduces maintenance needs and extends system lifespan.Q: How are quality and identification ensured for each fitting?

A: Each fitting carries clear markings indicating grade, size, heat number, and the manufacturers logo, ensuring full traceability. Supplied with EN 10204 3.1/3.2 test certificates, every piece is verified for compliance with ASTM B564 and ASME SB564 standards.Q: What sizes, grades, and connection types are available?

A: Monel forged fittings are available in sizes from 1/8 NB to 4 NB, with custom diameters and thicknesses (Sch 10 to Sch XXS) available upon request. Options include Monel 400 or Monel K500 grades, socket weld or threaded connections, and various shapes like tees, elbows, couplings, unions, caps, and plugs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Forged Fittings Category

Inconel Forge Fittings

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other, Pickled, Passivated

Material : Other , Inconel

Connection : Socket Weld, Threaded

Standard : Other, ASTM B564 / ASME SB564

Swage Nipple

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other, Pickling, Sand Blasting, Galvanization

Material : Other , Stainless Steel, Carbon Steel, Alloy Steel

Connection : Threaded, Buttweld

Standard : Other, ASTM A234, ANSI B16.9, MSS SP95

Sockolet

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other, Antirust Oil, Black Paint, Pickling

Material : Other , Carbon Steel, Stainless Steel, Alloy Steel

Connection : Welded

Standard : Other, ASME B16.11, MSSSP97, ASTM A105, ASTM A182

High Pressure Fittings

Price 250 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other, Passivated, ElectroPolished

Material : Stainless Steel

Connection : Threaded / Welded

Standard : Other, ASTM / ASME / DIN / JIS

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry