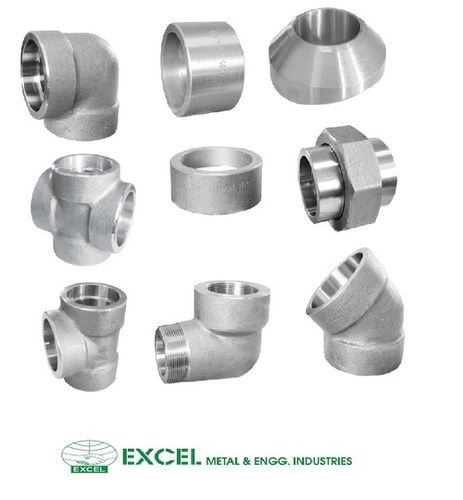

Socket Weld Elbow

Price 1500 INR/ Piece

MOQ : 10 Pieces

Socket Weld Elbow Specification

- Product Type

- Socket Weld Elbow

- Material

- Stainless Steel / Carbon Steel / Alloy Steel

- Type

- Forged Elbow Fitting

- Technics

- Forged

- Shape

- Elbow (90 Degree / 45 Degree)

- Connection

- Socket Weld

- Standard

- ASME B16.11 / ANSI B16.9 / MSS SP-79 / MSS SP-83

- Finishing

- Polished

- Surface Treatment

- Rust Proof Oil Coated / Pickled

- Size

- 1/8 to 4 (DN6 to DN100)

- Grade

- ASTM A105 / ASTM A182 F304 / F316 / F321

- Diameter

- DN6 - DN100

- Thickness

- SCH 10 / SCH 40 / SCH 80 / SCH 160

- Ends

- Socket Weld Ends as per ASME B16.11

- Feature

- Corrosion Resistant, High Strength, Leak Proof

- Color

- Silver/Grey

- Pressure Rating

- 2000 lbs, 3000 lbs, 6000 lbs, 9000 lbs

- Manufacturing Standard

- IBR, NACE compliant on request

- Installation

- Welded to pipe via socket for permanent joint

- Temperature Range

- Up to 750°C (Depending on material grade)

- Inspection

- 100% Dimension & Crack Test Inspection

- Packing

- Export Sea Worthy Wooden Box or as per requirement

- Application

- Pipe Fitting, Oil & Gas, Petrochemical, Industrial Piping Systems

Socket Weld Elbow Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Socket Weld Elbow

Socket Weld Elbow is a forged fitting element which is designed to make sturdy and durable fluid flow systems in industrial facilities and various buildings. It is made up by using best in class engineering materials that are provided with an anti-corrosive coating that makes it highly resistance to impact forces and rust which results in longer service life. Socket Weld Elbow availed by us is machined with high precision which gives excellent accuracy in dimensions for easy installations.

Reliable Performance Across High-Pressure Applications

Socket Weld Elbows are engineered for use in demanding environments like oil & gas and petrochemical piping systems. With forged construction, these elbows offer enhanced strength, leak resistance, and corrosion protection, ensuring reliable performance under pressure ratings up to 9000 lbs. Their polished and rust-proof finishes provide long-lasting durability and operational safety.

Versatile Material & Sizing Options

The elbows are available in materials such as stainless steel, carbon steel, and alloy steel. Supported by grade specifications including ASTM A105, ASTM A182 F304, F316, and F321, and sized from 1/8 inch to 4 inches (DN6 to DN100), they cater to varied system requirements. Multiple wall thicknesses (SCH 10, SCH 40, SCH 80, SCH 160) offer further customization.

Strict Quality Assurance & Compliance

Each Socket Weld Elbow is manufactured under stringent standards, including ASME B16.11 and IBR, with 100% dimension and crack inspection. NACE compliance is available on request, ensuring suitability for severe service environments. Export packing in sturdy wooden boxes secures elbows during worldwide shipment.

FAQs of Socket Weld Elbow:

Q: How is a Socket Weld Elbow installed in a piping system?

A: The elbow is welded to the pipe by inserting the pipe into its socket end, followed by fillet welding around the joint. This creates a permanent, leak-proof connection suitable for high-pressure applications.Q: What are the available pressure ratings for Socket Weld Elbows?

A: These elbows come in pressure ratings of 2000, 3000, 6000, and 9000 lbs, providing flexibility for use in both moderate and high-pressure industrial systems.Q: When should I use a forged Socket Weld Elbow compared to other elbow types?

A: Forged Socket Weld Elbows are ideal for scenarios that demand superior strength, high-pressure resistance, and compact piping configurations, such as oil & gas production and petrochemical processing facilities.Q: Where are Socket Weld Elbows commonly applied?

A: They are widely used in oil & gas pipelines, petrochemical plants, industrial piping systems, and other areas where robust, permanent joints are required for managing fluids under pressure.Q: What inspection processes ensure product quality?

A: Each elbow undergoes 100% dimension and crack testing before dispatch, ensuring compliance with applicable standards like ASME B16.11. NACE conformity is optionally available for critical service environments.Q: How does the material grade affect temperature resistance of the elbow?

A: Temperature tolerance (up to 750C) depends on the elbows material grade, with options such as ASTM A105, ASTM A182 F304, F316, and F321 providing varying levels of thermal stability and corrosion protection.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Forge Fitting Category

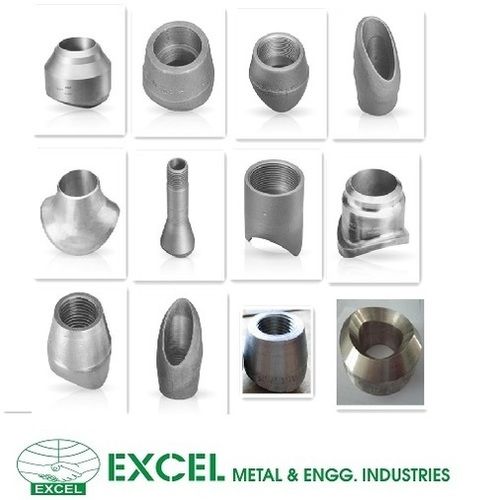

Nippolet

Price 1500 INR / Piece

Minimum Order Quantity : 10 Pieces

Finishing : Other, Black, Galvanized, Antirust Oil Coated

Standard : Other, ASTM/ASME A105, A182, A350, A694, A234

Product Type : Other, Nippolet

Thickness : As per Schedule (SCH) 10, 20, 40, 80, 160, XXS

Threaded Forged Fittings

Price 1500 INR / Piece

Minimum Order Quantity : 10 Pieces

Finishing : Other, Black, Galvanized, Polished

Standard : Other, ASTM A182, ASME B16.11, MSSSP79/83/95/97

Product Type : Other, Threaded Forged Fittings

Thickness : Sch 10S, 20, 40, 80, 160

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry