Nippolet

Price 1500 INR/ Piece

Nippolet Specification

- Product Type

- Nippolet

- Material

- Carbon Steel / Alloy Steel / Stainless Steel

- Type

- Forged Pipe Fitting

- Technics

- Forged

- Shape

- Round

- Connection

- Welded

- Standard

- ASTM/ASME A105, A182, A350, A694, A234

- Finishing

- Black, Galvanized, Anti-rust Oil Coated

- Surface Treatment

- Shot Blasted / Pickled

- Size

- 1/2 to 36 NB

- Grade

- ASTM A105, A182 F304/316, A350 LF2, A234 WPB

- Diameter

- Custom as per requirement

- Thickness

- As per Schedule (SCH) 10, 20, 40, 80, 160, XXS

- Heat Treatment

- Normalized, Quenched & Tempered

- End Connection

- Butt-weld, Socket-weld, Threaded

- Hardness

- Standard as per ASTM/ASME specification

- Corrosion Resistance

- High

- Pressure Rating

- CL 3000, CL 6000, CL 9000

- Usage/Application

- Oil & Gas, Chemical, Power, Shipbuilding, Plant Construction

Nippolet Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Nippolet

| Brand | as per requirement |

| Thread Size | as per std / customize / requirement |

| Material | as per std / customize / requirement |

| Standard | as per std / customize / requirement |

| Length | as per std / customize / requirement |

| Size | 1/2 inch, 3 inch, 3/4 inch, 1 inch, 2 inch |

| Application | Structure Pipe, Hydraulic Pipe, Pneumatic Connections, Gas Pipe, Chemical Fertilizer Pipe |

Nipolet : 1/2" to 24" in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

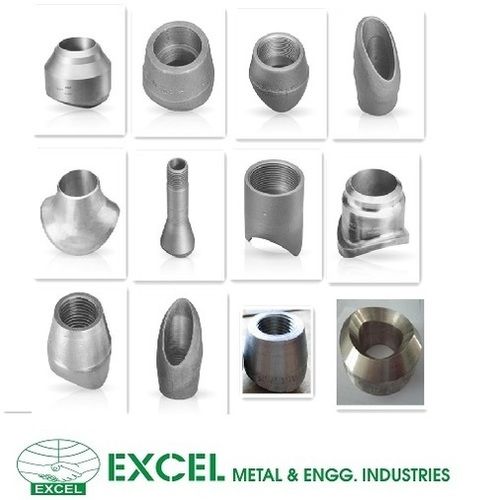

Other Outlet's

Sockolet

Elbolet

Threadolet

Nipolet

Letrolet

Swepolet

Stainless Steel Nipolet

Standard : ASTM / ASME A/SA 182

Grade : F 304, 304L, 304H, 309S, 309H, 310S, 310H, 316, 316TI, 316H, 316L, 316LN, 317, 317L, 321, 321H, 347, 347H, 904L.

Carbon Steel Nipolet

Standard : ASTM A105/A694/ A350 LF3/A350 LF2.

Grade : F42/46/52/56/60/65/70

Alloy Steel Nipolet

Standard : ASTM A182

Grade : F1/F5/F9/F11/F22/F91

Copper Alloy Nipolet

Standard : ASTM / ASME SB 61 / 62 / 151 / 152

Grade : UNS NO. C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30) C 71640

Nickel Alloy Nipolet

Standard :

ASTM / ASME SB 564 / 160 / 472

Nickel 200 Nipolet / UNS N02200

Nickel 201 Nipolet / UNS N02201

Monel 400 Nipolet / UNS N04400

Monel K500 Nipolet / UNS N05500

Inconel K600 Nipolet / UNS N06600

Inconel 601 Nipolet / UNS N06601

Inconel 625 Nipolet / UNS N06625

Inconel 800 Nipolet / UNS N08800

Inconel 800H Nipolet / UNS N08810

Inconel 825 Nipolet / UNS N08825

Hastelloy C276 Nipolet / UNS N10276

Alloy 20 Nipolet / UNS N08020

TEST CERTIFICATE

Manufacturer Test Certificate as per EN 10204 / 3.1

Versatile Connection Options

Nippolets are designed to fit multiple piping systems through butt-weld, socket-weld, or threaded end connections. This adaptability ensures they can integrate with most pipeline setups, supporting both old and new installations in diverse industrial environments. Their precision forging process guarantees durability and reliability even under demanding conditions.

Industry Grade Materials & Standards

Manufactured as per ASTM/ASME standards (A105, A182, A350, A694, A234), each Nippolet meets rigorous requirements for hardness, corrosion resistance, and pressure tolerance. Available in grades like A105, A182 F304/316, A350 LF2, and A234 WPB, with surface finishes such as shot blasted, pickled, black, galvanized, or anti-rust oil-coated. Diameters and thicknesses are customizable as per schedule and application needs.

Comprehensive Industrial Applications

Nippolets excel in critical sectors including oil & gas, chemicals, power generation, shipbuilding, and plant construction. Their high-pressure resistance and superior corrosion protection make them ideal for handling aggressive media and harsh environments, contributing to safety and operational efficiency. Available from manufacturers, distributors, exporters, and suppliers throughout India.

FAQs of Nippolet:

Q: How are Nippolets connected to piping systems?

A: Nippolets offer multiple end connection options, including butt-weld, socket-weld, and threaded types. The connection method is chosen based on pipe specifications and application requirements, enabling secure and leak-proof integration into various pipeline systems.Q: What industries commonly use Nippolet forged pipe fittings?

A: Nippolet fittings are widely utilized in sectors such as oil & gas, chemical processing, power generation, shipbuilding, and plant construction, thanks to their reliability, pressure handling capacity, and compliance with international standards.Q: When should I specify the pressure rating and schedule for Nippolets?

A: Pressure ratings (CL 3000, 6000, 9000) and pipe schedules (SCH 10, 20, 40, 80, 160, XXS) should be determined during system design, based on the operating pressure, temperature, and medium in your pipeline. Custom options allow precise matching to your project needs.Q: Where are Nippolets typically sourced in India?

A: Nippolets can be sourced from reputable manufacturers, distributors, exporters, and suppliers across India. Its important to select vendors who comply with ASTM/ASME standards and offer material traceability and certification for quality assurance.Q: What is the process for customizing Nippolet diameter and thickness?

A: Customization for Nippolet diameter and thickness is available as per client requirements. Customers provide specifications, such as size (1/2 to 36 NB) and schedule, and manufacturers fabricate the fittings accordingly, ensuring proper fit and compliance with project standards.Q: How does heat treatment influence Nippolet properties?

A: Nippolets undergo heat treatments like normalization and quenching & tempering, enhancing their mechanical strength, toughness, and resistance to fatigue and corrosion. These treatments are performed according to ASTM/ASME specifications and contribute to their longevity in demanding conditions.Q: What are the benefits of advanced surface treatments on Nippolets?

A: Advanced surface treatments including shot blasting, pickling, black, galvanized, and anti-rust oil coatings significantly improve Nippolet corrosion resistance and surface integrity. This extends their service life, particularly in harsh industrial environments where protection against chemical agents is vital.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

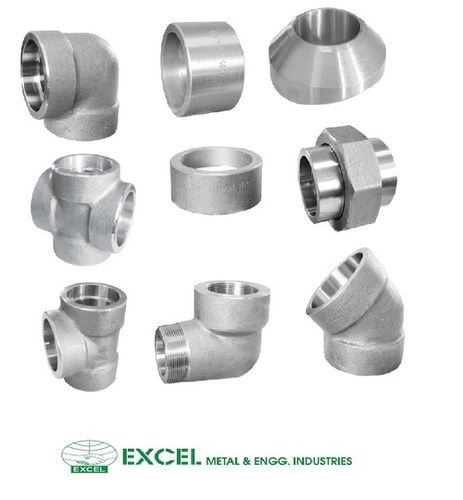

More Products in Forge Fitting Category

Socket Weld Elbow

Price 1500 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other, Rust Proof Oil Coated / Pickled

Material : Other , Stainless Steel / Carbon Steel / Alloy Steel

Diameter : DN6 DN100

Thickness : SCH 10 / SCH 40 / SCH 80 / SCH 160

Threaded Forged Fittings

Price 1500 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Other, RustProof Oil, Pickling, Sand Blasting

Material : Other , Carbon Steel, Stainless Steel, Alloy Steel

Diameter : 6 mm to 100 mm

Thickness : Sch 10S, 20, 40, 80, 160

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry