Plasma Torch Coolant

Plasma Torch Coolant Specification

- Temperature Range

- -20C to +120C

- Product Type

- Plasma Torch Coolant

- Material

- Proprietary Coolant Fluid (Glycol Based)

- Shape

- Liquid

- Standard

- OEM Grade

- Color

- Pink

- Usage

- Torch Cooling System

- Application

- Plasma Cutting Machine Coolant

- Material Grade

- Industrial Grade

Plasma Torch Coolant Trade Information

- Minimum Order Quantity

- 300 Bags

- FOB Port

- Navaseva

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Main Domestic Market

- Himachal Pradesh, Andaman and Nicobar Islands, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, North India, East India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Pondicherry, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Uttar Pradesh, Punjab, Central India, Odisha, West India, Chhattisgarh, All India

- Certifications

- ISO 9001

About Plasma Torch Coolant

| Packaging Type | Barrel, Drum |

| Grade | Plasma Cutting Machine Coolant |

| Packaging Size | 3 / 5 / 10 / 50 / 100 LTR |

| Physical State | LIQUID |

| Packaging Size (litres) | 3/5/10/50/100 LTR |

| Pack Size (Litre) | 5/10/30/50/100 |

| Usage/Application | Plasma Machine |

Plasma Torch Coolant for CNC plasma cutting tables, generate a lot of heat. It clearly takes high temperatures to melt and cut metals cleanly and accurately.

The problem is that the heat that cuts thick pieces of metal can also melt the plasma torch's electrode, nozzle, and even the torch itself, if left unchecked. That's where the plasma cooling system goes to work and coolant is a crucial part of the system.

At present we are supplying Plasma Torch Coolant machine cooling to Hypertherm , kejellberg, thermo Dynamic & ESAB

Advanced Dielectric Cooling Fluid

Our plasma torch coolant fluid features low electrical conductivity, making it an ideal dielectric solution for modern torch cooling systems. By preventing electrical current flow within the torch, it safeguards sensitive components and ensures optimal operational stability. The glycol-based formula is specifically designed for demanding industrial plasma cutting environments, reducing equipment downtime and prolonging service life.

Comprehensive Corrosion Protection

Engineered with strong anti-corrosive additives, this coolant actively protects internal parts of your plasma cutting system from rust and scaling. Maintaining a neutral pH value between 7.5 and 8.5, it helps prevent chemical deterioration, ensuring that all metallic and non-metallic torch components remain in peak condition throughout the coolants 24-month shelf life.

FAQs of Plasma Torch Coolant:

Q: How do I use the plasma torch coolant in my cutting machine?

A: To use, simply fill your plasma torchs designated coolant reservoir with the liquid from the 5-litre plastic bottle, ensuring all instructions in your machines manual are followed. Run the system to circulate the coolant throughout the cooling circuit before operating the torch.Q: What are the benefits of using this proprietary glycol-based coolant fluid?

A: This coolant delivers exceptional torch cooling and thermal stability, minimizes the risk of freezing or boiling, and protects your equipment from internal corrosion, thus extending overall lifespan and performance reliability of plasma torches.Q: When should I replace the plasma torch coolant?

A: Coolant replacement should be performed as per your plasma cutting machines maintenance schedule or when it shows signs of contamination, discoloration, or diminished performancetypically within the products 24-month shelf life.Q: Where should I store the plasma torch coolant for maximum shelf life?

A: Store the coolant in its original plastic bottle, tightly closed, in a cool, dry place away from direct sunlight. This helps preserve its anti-corrosive and dielectric properties for up to 24 months.Q: What makes this coolant suitable for all major plasma torches?

A: Formulated to OEM-grade industrial standards, the coolants non-flammable, odorless, and low-conductivity properties make it compatible with leading plasma torch brands, ensuring safe and effective cooling across a wide temperature range.Q: How does the coolant protect plasma torch systems from corrosion?

A: The coolant is enhanced with advanced anti-corrosive agents and maintains a neutral pH level, shielding metal and non-metal components in the cooling circuit from rust and chemical deterioration.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

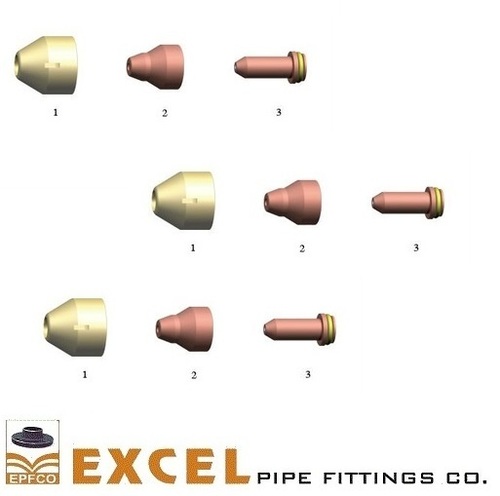

More Products in Plasma Spare Parts Category

Thermal Dynamics Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Section Shape : Other, Cylindrical

Product Type : Other, Plasma Consumables

Connection : Other, Slip Fit/Threaded

Kjellberg Plasma Consumables

Price Range 500.00 - 5000.00 INR / Bag

Minimum Order Quantity : 300 Bags

Section Shape : Other, Cylindrical

Product Type : Other, Plasma Consumables

Connection : Other, Press Fit

Plasma Spare Parts

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags, ,

Section Shape : Other, Round, Flat, Custom

Product Type : Other, Plasma Spare Parts

Connection : Other, Socket, Threaded, Slipon

Thermal Dynamics Nozzle

Price 200 INR / Bag

Minimum Order Quantity : 300 Bags

Section Shape : Round

Product Type : Other, Plasma Cutting Nozzle

Connection : Other, Pushfit

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry