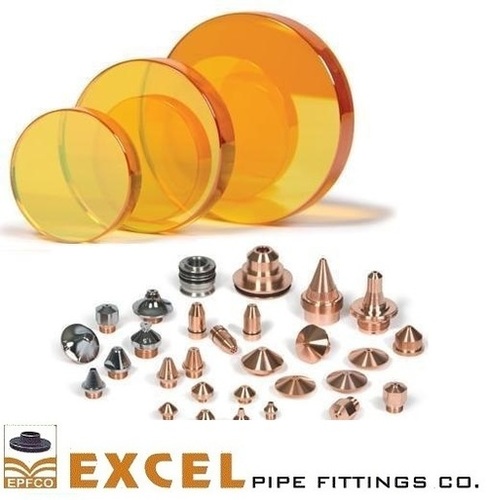

Plasma Spare Parts

Plasma Spare Parts Specification

- Connection Type

- Direct Fit, Adapter Based

- Diameter

- Up to 25 mm

- Thread Type

- Metric, BSP, NPT

- Coating Type

- Nickel, Tin, Ceramic

- Sealing Type

- O-Ring, Metal to Metal

- Flexibility

- Rigid

- Tolerance

- 0.02 mm

- Tensile Strength

- Up to 350 MPa

- Yield Strength

- Up to 230 MPa

- Temperature Range

- -20C to 200C

- Product Type

- Plasma Spare Parts

- Material

- Copper, Brass, Ceramic, Stainless Steel

- Connection

- Socket, Threaded, Slip-on

- Shape

- Cylindrical, Circular, Rectangular, Customized

- Standard

- ISO 9001:2015

- Surface Treatment

- Nickel Plated, Polished, Coated

- Outer Diameter

- 0.5 mm to 25 mm

- Section Shape

- Round, Flat, Custom

- Length

- Up to 100 mm

- Thickness

- 1 mm to 10 mm

- Color

- Copper, Silver, Gold, Black

- Usage

- Plasma Cutting Torch, CNC Plasma Machines

- Rated Pressure

- Up to 10 Bar

- Application

- Industrial Plasma Cutting, Welding Automation

- Material Grade

- High Conductivity Copper, Grade 304/316 Stainless Steel

Plasma Spare Parts Trade Information

- Minimum Order Quantity

- 300 Bags, ,

- Supply Ability

- 1 Bag Per Day

- Delivery Time

- 1 Week

About Plasma Spare Parts

| Brand | PLASMA CONSUMABLES |

| Usage/Application | as per std / requirement |

| Model | as per std / requirement |

| Fuel Gas Type | as per std / requirement , LPG, Hydrogen, Oxy-Acetylene |

| Cutting Capacity (mm) | as per std / requirement |

| Weight (kg) | as per std / requirement |

| Finishing | as per std / requirement |

| Material | as per std / requirement |

| Consumable Type | Torch, Rod, Wire, Electrodes, Spare Part |

| Packaging (quantity per box) | as per std / requirement |

Features

AJANHP100-200

HP130-260

CP161

CP200

PT-24

PT-600

MERLIN 1000-3000-6000 GTS

SL60-100

POWERMAX 1000

POWERMAX 1250

POWERMAX 1650

POWERMAX 30

POWERMAX 45

POWERMAX 65-85-105

MAX200

HT2000

HT2000 HYSPEED

HPR HD3070 UPGRADE

HPR HD4070 UPGRADE

HPR130

HPR260

HPR130XD

HPR260XD

HPR400XD

HSD130 HYSPEED

PA-S20-25-40-45W

PA-S47 W

HIFOCUS 80I

HIFOCUS 100

HIFOCUS 130

HIFOCUS 280I-360I-440I (160A)

HIFOCUS 280I-360I-440I (440A)

HIFOCUS 280I-360I-440I YELLOWXLIFE

FINEFOCUS 800-900-1600

FINEFOCUS 800-900-1600-PLUS

PA-S50-75-76-77-150

HIFOCUS 280I-360I-440I (200A)

FINEFOCUS 800-900-1600-PLUS (400A)

OCP 150

Request

Callback

Versatile Compatibility for Industrial Needs

Our plasma spare parts are designed for seamless compatibility with most standard plasma torches, making them ideal for CNC plasma machines and diverse industrial applications. A comprehensive array of sizes, shapes, and material grades ensures reliable integration for distributors, manufacturers, and end-users across the sector.

Engineered for Durability and Performance

These spare parts maintain structural integrity under rigorous conditions, with high hardness (up to 90 HRB), superior corrosion resistance, and robust surface coatings such as nickel or tin. Each part undergoes precision manufacturing to a tolerance of 0.02 mm, providing consistent performance and longevity in demanding environments.

Flexible Packing and Customization Options

Choose from individual or set packings with protective covers to suit your maintenance and operational preferences. Custom shapes, sizes, and finishes are available upon request, ensuring that you get optimal fit and functionality for your unique plasma cutting or automation setup.

FAQs of Plasma Spare Parts:

Q: How do I choose the right plasma spare part for my torch or machine?

A: Identify your torch model and review the specifications such as mounting type (screw, clamp, direct placement), size requirements, and material compatibility (copper, brass, ceramic, stainless steel). Our spare parts are compatible with most standard plasma torches and feature direct-fit or adapter-based connections.Q: What is the typical replacement cycle for plasma spare parts?

A: Replacement frequency depends on usage intensity, with an average lifespan ranging from 50 to 200 hours. Regular inspection for wear is recommended to maintain optimal cutting performance and prevent unplanned downtime.Q: Where can these plasma spare parts be used?

A: They are suitable for a wide range of applications including industrial plasma cutting, welding automation, and CNC plasma machines. Our products are distributed, exported, and supplied throughout India and internationally.Q: What benefits does high corrosion resistance provide for plasma cutting operations?

A: High corrosion resistance ensures that the spare parts maintain their mechanical and conductive properties over time, even in harsh working environments. This leads to fewer replacements, reduced maintenance, and more reliable cutting outcomes.Q: How are plasma spare parts packaged and protected during shipment?

A: Each part is securely packed either individually or in sets, equipped with protective covers to prevent damage during handling and transport. This careful packaging preserves the surface treatment and critical dimensions of every component.Q: What manufacturing standards do these plasma spare parts comply with?

A: Our spare parts are manufactured to meet ISO 9001:2015 quality management standards, ensuring precise tolerances, consistent quality, and trustworthy performance for industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Plasma Spare Parts Category

Hypertherm Nozzle

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Surface Treatment : Other, Electroplated

Material : Other , Copper Alloy

Shape : Other, Cylindrical

Thermal Dynamics Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Surface Treatment : Other, Nickel Plated

Material : Other , Copper Alloy

Shape : Other, Round/Custom

Plasma Consumables

Price Range 50.00 - 500.00 INR / Bag

Minimum Order Quantity : 300 Bags

Surface Treatment : Other, Polished

Material : Other , Copper, Silver Plated

Shape : Round

Trumpf Laser Consumable

Price 500 INR / Bag

Minimum Order Quantity : 300 Bags

Surface Treatment : Other, Polished

Material : Other , Copper Alloy

Shape : Round

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry