Hastelloy Fittings

Price 3000 INR/ Piece

Hastelloy Fittings Specification

- Yield Strength

- 283 MPa - 352 MPa

- Thread Type

- NPT / BSP / BSPT / Metric

- Flexibility

- Rigid

- Diameter

- 8 mm - 610 mm

- Sealing Type

- Metal-to-metal / Gasket (for threaded)

- Temperature Range

- -196C to 870C

- Tensile Strength

- 690 MPa - 900 MPa

- Connection Type

- Welded / Male-Female / Screwed

- Tolerance

- 0.1 mm

- Bend Radius

- Standard radius / customized

- Coating Type

- Uncoated / Custom Coated

- Product Type

- Fitting

- Material

- Hastelloy (Nickel-based alloy)

- Connection

- Butt Weld, Socket Weld, Threaded

- Shape

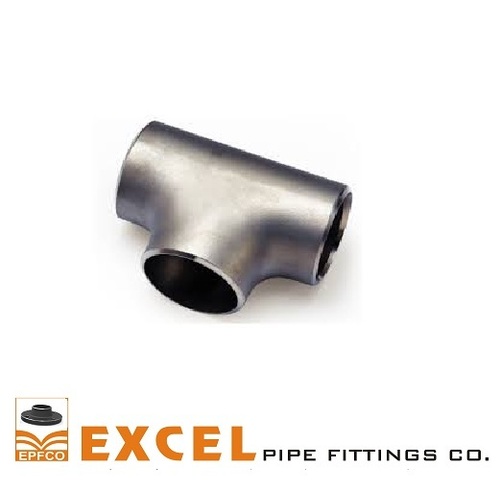

- Elbow, Tee, Reducer, Coupling, Stub End, Cross, Cap

- Standard

- ASTM B366 / ASME SB366 / ANSI / DIN / JIS / BS

- Surface Treatment

- Polished / Pickling / Passivated

- Outer Diameter

- 1/8 NB - 24 NB (Nominal Bore)

- Section Shape

- Round

- Length

- As per requirement / standard lengths

- Thickness

- 1.5 mm to 20 mm

- Color

- Metallic Silver, Grey

- Usage

- High temperature, corrosive environments, chemical industry

- Rated Pressure

- Up to 6000 psi

- Application

- Chemical Processing, Gas Processing, Pharmaceuticals, Petrochemicals, Power Generation

- Material Grade

- Hastelloy C22, C276, B2, X, G30

- Hardness

- Rockwell B90 to B100

- End Type

- Plain End, Bevel End, Threaded End

- Wall Thickness Range

- Schedule 10S, 40S, 80S, 160S, XXS

- Manufacturing Process

- Forged and Machined

- Available Sizes

- 1/8 NB to 24 NB (seamless), up to 48 NB (welded)

- Corrosion Resistance

- Excellent to strong acids and oxidizers

- Testing

- 100% Radiography, Hydrostatic Tested

- Compliance

- NACE MR0175, ISO 9001:2015

- Packaging

- Export Standard Wooden Cases

- Density

- 8.89 g/cm

Hastelloy Fittings Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Hastelloy Fittings

| Hastelloy | Nickel Alloy |

| Brand | as per std / customize / requirement |

| Material | as per std / customize / requirement |

| Application | as per std / customize / requirement |

| Size | as per std / customize / requirement |

| Grade | as per std / customize / requirement |

| Thread Size | as per std / customize / requirement |

| Condition | New |

| Size (inch) | as per std / customize / requirement |

Hastelloy Forged Pipe fittings

Forged Fittings

1/4 NB to 4 NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Outlet's

1/4 to 24 in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Type

Socket Weld (S/W) & Screwed (SCRD)

Form

Elbow 45 deg & 90 degree, Tee , Union, Full & Half coupling, Cross, Cap, Swage Nipple, Plug, Bush

Outlet's

Weldolet, Sockolet, Elbolet, Threadolet, Nipolet, Letrolet, Swepolet

Grade

Hastelloy C276 Pipefittings UNS N10276

Exceptional Corrosion Resistance

Hastelloy fittings are specifically designed to withstand highly corrosive environments, offering superior resistance to strong acids and oxidizing agents. This makes them an excellent choice for industries such as chemical processing, pharmaceuticals, and gas processing, where material degradation can compromise safety and efficiency.

Versatile Applications and Configurations

These fittings are available in a wide range of shapes, including elbows, tees, reducers, couplings, stub ends, crosses, and caps. They can be customized in diameters ranging from 8 mm to 610 mm, and are suitable for butt weld, socket weld, and threaded connections, supporting various piping layouts and technical requirements.

Rigorous Quality and Safety Standards

Manufactured under strict compliance with international standards such as ASTM, ASME, ANSI, DIN, and JIS, Hastelloy fittings are 100% radiography and hydrostatic tested. This ensures robust structural integrity and reliability, even at pressures up to 6000 psi and temperatures from -196C to 870C.

FAQs of Hastelloy Fittings:

Q: How are Hastelloy fittings manufactured to ensure quality and precision?

A: Hastelloy fittings are produced using forging and precision machining processes, followed by surface treatments like polishing, pickling, or passivation. Each fitting undergoes 100% radiography and hydrostatic testing to verify strength and consistency as per ASTM B366 and ASME SB366 standards.Q: What are the main benefits of using Hastelloy fittings in corrosive environments?

A: The primary advantage of Hastelloy fittings is their outstanding resistance to strong acids, oxidizers, and corrosive chemicals. This durability prolongs service life, reduces maintenance costs, and enhances safety in critical applications such as chemical processing, gas handling, and power generation.Q: Where can Hastelloy fittings be applied most effectively?

A: These fittings are widely utilized in industries like chemical processing, pharmaceuticals, petrochemicals, gas processing, and power generation. They are particularly valued in environments that require high performance under elevated temperatures and aggressive chemical exposure.Q: What compliance standards do Hastelloy fittings meet?

A: Hastelloy fittings are manufactured in accordance with major international standards such as ASTM B366, ASME SB366, NACE MR0175, ISO 9001:2015, and other specifications like ANSI, DIN, JIS, and BS, ensuring their suitability for global industrial projects.Q: When should various end types and connection options be selected for Hastelloy fittings?

A: The choice of end typeplain, bevel, or threadeddepends on installation and piping system needs. For welded connections, bevel or butt-weld ends are used, while threaded ends are suitable for male/female or screwed piping systems. Selection should align with operational pressures, media, and leakage prevention requirements.Q: What wall thickness and size options are available for these fittings?

A: Hastelloy fittings are offered in wall thicknesses ranging from Schedule 10S to XXS and diameters from 1/8 NB to 24 NB (seamless) or up to 48 NB (welded). Custom lengths and bend radii can be provided to meet project-specific demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Buttweld Fittings Category

Hastelloy Pipe Fittings

Price 3000 INR / Piece

Minimum Order Quantity : 10 Pieces

Connection : Other, Welded, Threaded

Material : Other , Hastelloy

Shape : Other, Elbow, Tee, Reducer, Coupling, Cap, Nipple

Product Type : Other, Pipe Fittings

Monel Pipe Fittings

Price 3000 INR / Piece

Minimum Order Quantity : 10 Pieces

Connection : Other, Welded, Threaded

Material : Other , Monel (NickelCopper Alloy)

Shape : Other, Elbow, Tee, Reducer, Coupling, Cap

Product Type : Other, Pipe Fittings

Monel Fittings

Price 3000 INR / Piece

Minimum Order Quantity : 10 Pieces

Connection : Other, Butt Weld, Socket Weld, Threaded

Material : Other , Monel Alloy

Shape : Other, Elbow, Tee, Reducer, Coupling, Union, Cap, Nipple

Product Type : Other, Pipe Fittings

Alloy 20 Fittings

Price 3000 INR / Piece

Minimum Order Quantity : 10 Pieces

Connection : Other, Butt Weld, Socket Weld, Threaded

Material : Other , Alloy 20 (NickelIronChromium Alloy)

Shape : Other, Elbow, Tee, Reducer, Coupling, Cap

Product Type : Other, Pipe Fittings

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry