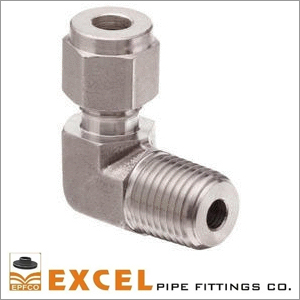

Elbow Fittings

Price 110 INR/ Piece

Elbow Fittings Specification

- Product Type

- Elbow Fittings

- Material

- Stainless Steel

- Type

- 90 Degree Elbow

- Shape

- Elbow

- Technique

- Forged

- Surface Treatment

- Polished

- Standard

- ASTM, DIN, ANSI

- Outer Diameter

- 21.3 mm to 165.1 mm

- Length

- As per specification

- Inside Diameter

- 15 mm to 150 mm

- Wall Thickness

- Sch 10 to Sch 160

- Tensile Strength

- 490 MPa minimum

- Grade

- SS304/SS316

- Size

- 1/2 inch to 6 inches

- Color

- Silver

Elbow Fittings Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Week

About Elbow Fittings

| Head Code | Square, Hexagon |

| Elbow Type | AS PER STD OR REQ |

| Elbow Bend Angle | 60 Degree, 90 Degree, 30 Degree, 45 Degree |

| Connection | Welded, Flange, Female, Male |

| Size | 1/4 inch-1 inch, 1 inch-2 inch, 2 inch-3 inch, 3 inch-10 inch, 10 inch-20 inch, >20 inch |

| Application | Hydraulic Pipe, Structure Pipe, Gas Pipe, Chemical Fertilizer Pipe |

| Material | MS, Brass, Plastic, Copper, SS |

Elbow FittingsOur in-house production of Union Elbow is manufactured with excellent quality of raw materials to suit the fixing work mainly in electrical industries, air conditioning industries. These products of ours have been well demanded and extensively used by the clients of diverse category in different size. These Elbows have part numbers of numerous kinds to select from.

- Union Elbow

- Street Elbow

- Male Elbow

Engineered for Challenging Environments

Our stainless steel elbow fittings are forged to provide exceptional strength and durability for a broad range of industrial applications. With wall thickness options from Sch 10 to Sch 160 and a minimum tensile strength of 490 MPa, these elbows ensure reliable performance even in demanding conditions such as high temperatures and corrosive environments.

Versatile and Customizable Solutions

Available in a variety of sizes, pressure ratings, and diameters, our elbows are crafted to meet specific project requirements. Clients can select from beveled or plain end types, as well as customized lengths, to guarantee perfect integration into their existing systems, enhancing overall operational efficiency.

FAQs of Elbow Fittings:

Q: How are stainless steel elbow fittings used in industrial piping systems?

A: Stainless steel elbow fittings are used to change the direction of fluid flow within piping systems in industries such as oil, gas, water supply, and general industrial processes. The 90-degree elbows enable efficient routing of pipes, accommodating space constraints and complex layouts.Q: What makes these elbow fittings suitable for corrosive environments?

A: These fittings are made from premium grades SS304 and SS316 stainless steel, offering excellent corrosion resistance. The polished surface and adherence to international standards ensure long-lasting performance even in aggressive or high-humidity environments.Q: When should I choose between welded and seamless connection types?

A: Seamless elbows are typically chosen for applications requiring higher integrity and strength, such as high-pressure lines, while welded elbows are cost-effective options for applications with moderate pressure and where some flexibility in fabrication is beneficial.Q: Where are these elbow fittings commonly installed?

A: These elbows are widely used in industrial piping systems, domestic and commercial plumbing, water supply networks, and oil and gas pipelines, both inside plants and in outdoor settings.Q: What is the process for manufacturing these stainless steel elbows?

A: The elbows are forged from high-quality stainless steel, followed by precise machining to achieve the desired dimensions. They are then polished and inspected according to ASTM, DIN, or ANSI standards before packaging in strong carton boxes or wooden cases for export.Q: How do I select the appropriate size and pressure rating for my application?

A: Determine the inside and outside diameters required for your system, then select the corresponding size (from 1/2 inch to 6 inches or 15 mm to 150 mm) and the suitable pressure rating (PN10 to PN40) based on the maximum operating pressure in your pipeline.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ferrule Fittings & Hydrollic Fittings Category

Male Connectors

Price 250 INR / Piece

Minimum Order Quantity : 50 Pieces

Technique : Other, Precision Machined

Standard : Other, ISO, DIN, ROHS Compliant

Material : Other, Brass/Nickel Plated Brass/Stainless Steel/Polymer

Surface Treatment : Other, Nickel Plated/Chromed/Polished

Ermeto Fittings

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Technique : Other, Cold Forged

Standard : Other, DIN 2353, ISO 84341

Material : Other, Carbon Steel, Stainless Steel or Brass

Surface Treatment : Other, Zinc Plated, Chromium Plated, Phosphated

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry