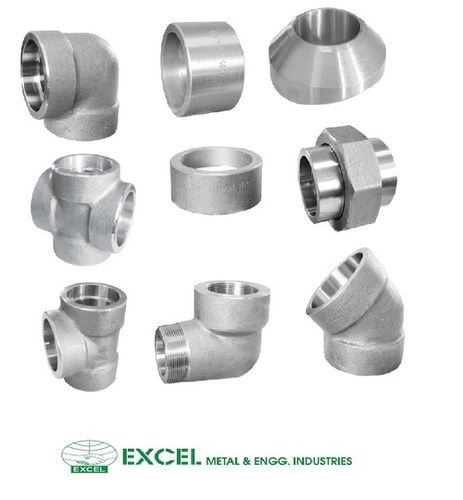

Threaded Forged Fittings

Price 1500 INR/ Piece

Threaded Forged Fittings Specification

- Product Type

- Threaded Forged Fittings

- Material

- Carbon Steel, Stainless Steel, Alloy Steel

- Type

- Elbow, Tee, Coupling, Union, Cap, Plug, Cross

- Technics

- Forged

- Shape

- Round, Equal, Reducing

- Connection

- Threaded (NPT/BSP)

- Standard

- ASTM A182, ASME B16.11, MSS-SP-79/83/95/97

- Finishing

- Black, Galvanized, Polished

- Surface Treatment

- Rust-Proof Oil, Pickling, Sand Blasting

- Size

- 1/8 to 4 (DN6 to DN100)

- Grade

- ASTM A105, F304, F316, F11, F22

- Diameter

- 6 mm to 100 mm

- Thickness

- Sch 10S, 20, 40, 80, 160

- Application

- Petroleum, Chemical, Power, Gas, Shipbuilding, Construction

- Color

- Silver, Black

- Pressure Rating

- 2000lbs, 3000lbs, 6000lbs, 9000lbs

- Marking

- Size, Pressure, Material Grade

- Working Temperature

- -29°C to 593°C

- Thread Type

- NPT, BSPP, BSPT

- End Connection

- Female / Male Threaded

- Corrosion Resistance

- High

- Manufacturing Process

- Hot Forged & Machined

Threaded Forged Fittings Trade Information

- Minimum Order Quantity

- 10 Pieces

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Threaded Forged Fittings

| Size | 2 inch |

| Application | Hydraulic Pipe |

| Material | AS SPEC / REQ |

| Type | Brass, Iron, Steel, Copper |

| Diameter | AS SPEC / REQ |

| Connection Type | Male, Welded, Female |

| Grade | AS SPEC / REQ |

We are one of the leading trader and supplier of Threaded Forged Pipe Fittings.

Features:

- Outstanding pipe handling

- Dimensional exactitude

- Fine finish

- High sustainability to elevated temperature and pressure

- Trouble free supply of materials

- Rust proof

- Chemical resistant

- Impeccable thread sealant

- High mechanical strength

- Simple to install and dismantle

High tensile strength Standard:

ASME/ANSI B16.5, ASME/ANSI B16.36, ASME/ANSI B16. 47 SERIES A (MSS SP-44), SERIES B (API 605), BS4504, EN1092-01, AWWA C207, UNI 2276-67, DIN, JIS, BS 10:1962, IS:6392-1971, API 6A etc.

Class: ASA (150#, 300#, 400#, 600#, 900#, 1500#, 2500#), BS 4504/EN 1092-01- (PN2.5, PN6, PN10, PN16, PN25, PN40, PN63/64, PN100, PN160, PN250, PN320, PN400), (JIS B2220, B2210), (UNI 2276-67, 2278-67, 2278-67), (IS TABLE 5, 11, 17), BS 10 (TABLE D,E,F,H,J,K,R), DIN (2576, 2527, 2641, 2642, 2638, 2628, 2629, 2630, 2631, 2632, 2633, 2634, 2635, 2627, 28115) AWWA (C207 Class B, D, E ), API 6A (2000PSI, 3000PSI, 5000PSI, 10000PSI), SAE Flanges 3000PSI, 6000PSI

High Strength and Versatile Applications

Threaded forged fittings offer exceptional durability and safety in demanding sectors like petroleum, chemical processing, gas, and shipbuilding. With pressure ratings up to 9000lbs and a broad working temperature range, they accommodate challenging operational environments with ease. Their superior manufacturing process and material integrity result in extended service life and optimal performance.

Wide Selection of Types and Standards

Available in elbows, tees, couplings, unions, caps, plugs, and crosses, these fittings are compliant with leading standards such as ASTM A182, ASME B16.11, and MSS-SP. They come in a variety of shapes (round, equal, reducing) and finishes like black, galvanized, and polished, ensuring compatibility across numerous systems and requirements.

FAQs of Threaded Forged Fittings:

Q: How are threaded forged fittings manufactured?

A: Threaded forged fittings are produced using a hot forging and machining process. High-quality steel is first heated and forged under high pressure, ensuring structural integrity and superior strength. The forged pieces are then precision-machined to achieve required thread types (NPT, BSPP, BSPT) and exact dimensions.Q: What are the main benefits of using these fittings in industrial applications?

A: These fittings provide high corrosion resistance, exceptional mechanical strength, and leak-proof connections. Their ability to withstand pressures up to 9000lbs and wide temperature range ensures reliability in demanding environments such as petroleum, chemical processing, power generation, and shipbuilding.Q: When should threaded forged fittings be used over welded fittings?

A: Threaded forged fittings are ideal when ease of installation, maintenance, or modification is required. They are particularly suited for systems where welding is impractical due to tight spaces, or when temporary connections are necessary, as in repairs or shorter pipelines.Q: Where can threaded forged fittings be installed?

A: These fittings are used extensively in industries like oil and gas, chemical processing, shipbuilding, and power plants. They are suitable for both indoor and outdoor piping systems, including areas exposed to harsh environments due to their high corrosion resistance and robust construction.Q: What marking and surface treatment options are available?

A: Each fitting is marked with size, pressure rating, and material grade for clear identification. Surface treatments include blackening, galvanization, polishing, rust-proof oil, pickling, or sand blasting, each tailored to enhance durability and protection against corrosive agents.Q: How do I select the correct threaded type for my piping system?

A: Thread type selection (NPT, BSPP, or BSPT) depends on the regional standard or system compatibility. NPT threads are commonly used in North America, while BSPP and BSPT are often required for European and Asian applications. Always verify thread compatibility before installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Forge Fitting Category

Socket Weld Elbow

Price 1500 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Other, Socket Weld Elbow

Finishing : Other, Polished

Size : 1/8 to 4 (DN6 to DN100)

Connection : Socket Weld

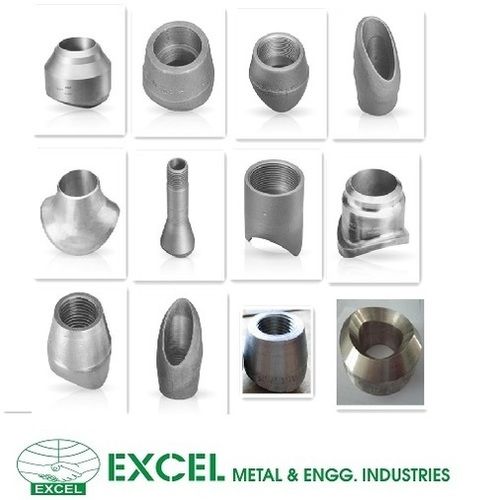

Nippolet

Price 1500 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : Other, Nippolet

Finishing : Other, Black, Galvanized, Antirust Oil Coated

Size : 1/2 to 36 NB

Connection : Welded

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry